Raw

materials

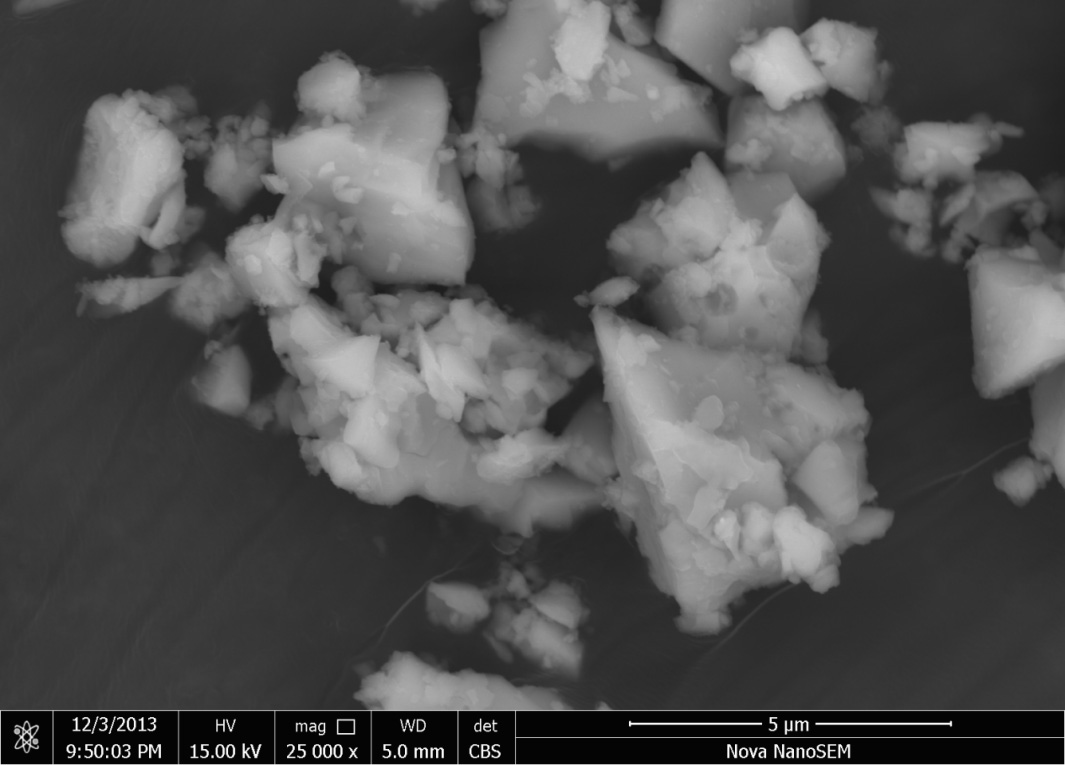

This product was produced by using industrial alumina powder and high-purity

limestone as raw materials.

Producing

After being smelted and cooled by

electric arc furna...

| Performance index | DK-68 | DK-71 | DK-80 | |

| Chemical composition (%) |

AL2O3 | ≥64 | ≥68 | ≥78 |

| CaO | ≤35 | ≤31 | ≤21 | |

| SiO2 | ≤0.5 | ≤0.4 | ≤0.3 | |

| Fe2O3 | ≤0.5 | ≤0.4 | ≤0.3 | |

| SBET(cm2/g) | ≥4500 | ≥4500 | ≥6000 | |

| 0.045mm Screen residue(%) | ≤15 | ≤10 | ||

| Setting time | Initial setting time(min) | ≥30 | ||

| Final setting time(min) | ≤360 | |||

| CCS/CMOR(MPa) | Maintenace 6h | ≥10/2 | ≥8/1.5 | |

| Maintenance 24h | ≥40/6 | ≥40/5 | ||

| Note | Setting time can be customized as per your requirements | |||

| Package | 25kg/bag | |||

| Specification | A600 | A700 | A900 | |

| Chemical components(%) | Al2O3 | ≥50.0 | ≥51.0 | ≥53.5 |

| CaO | ≤39.2 | ≤38.5 | ≤38 | |

| SiO2 | ≤7.8 | ≤7.5 | ≤5.5 | |

| Fe2O3 | ≤2.5 | ≤2.5 | ≤2.5 | |

| SBET(m2/kg) | ≥300 | ≥320 | ≥350 | |

| 0.045mm Screen residue(%) | ≤15 | ≤12 | ≤8 | |

| Setting time | Initial setting time(min) | ≥45 | ≥60 | ≥90 |

| Finnal setting time(min) | ≤360 | ≤360 | ≤360 | |

| CCS/CMOR(MPa) | Maintenance 24h | ≥45/6 | ≥55/6.5 | ≥72/8.0 |

| Test standard | GB/T17671&GB201-2000 | |||

| Package | 25kg/bag or as per customers' requirement | |||