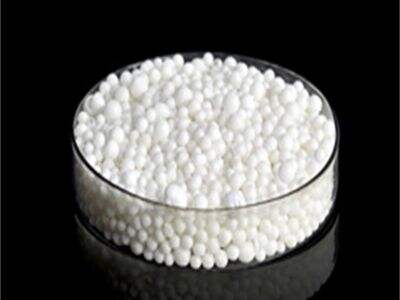

Hvid smeltet aluminiumoxid er et vigtigt materiale, der anvendes i alle typer slibemidler. Det er meget hårdt og kan bruges på mange måder, f.eks. til formning af slibepapir eller slibning af metaller.

Hvad er kornstørrelserne for hvid smeltet aluminiumoxid

Hvid smeltet aluminiumoxid har et bredt kornstørrelsesområde. Hver størrelse har sit formål. Kornstørrelsen angives typisk med et tal, hvor et lavere kornnummer indikerer en større størrelse, og højere kornnumre angiver mindre størrelser. For eksempel er 24 korn ekstremt groft og velegnet til kraftig slibning.

Introduktion

Brug af for grov kornstørrelse kan forårsage problemer i industrielle applikationer. Hvis du for eksempel vælger for grov kornstørrelse til en følsom opgave, kan du ridse overfladen eller slibe for meget materiale væk. Dette kan ødelægge det stykke, du arbejder på. Omvendt vil brug af for fin kornstørrelse til kraftig slibning tage alt for lang tid og måske slet ikke virke. Først og fremmest skal du forstå opgaven. Spørg dig selv om dette igen og igen.

Hvorfor er hvid smeltet aluminiumoxid korn det bedste

Hvid smeltet aluminiumoxid korn er et produkt af høj kvalitet, som fremstilles ved anvendelse af bauxit af god kvalitet som hovedmateriale, der smeltes ved høj temperatur, hvilket gør det solidt og kompakt. Materialet er hårdt og sejt. På grund af disse egenskaber er det fremragende til mange industrielle opgaver, herunder – men ikke begrænset til – opgaver, der kræver slibning eller polering.

Effekten af hvid smeltet aluminiumoxid kornstørrelser

Kornstørrelsen af hvid smeltet alumina binder er en meget vigtig faktor for afslutningskvaliteten. Forskellige kornstørrelser anvendes til forskellige opgaver. Hvis du ønsker overfladen meget glat, ville du bruge et finere korn. Slidest grits har finere partikler, der ikke efterlader ridser og kan polere overflader. Derimod, hvis du skal fjerne en masse materiale hurtigt, vil du vælge grovere papir. De større partikler i grove korn kan mere aggressivt skære igennem hårde overflader.

hvid smeltet aluminiumoxid Hvilke fordele kan opnås

Specielle korntyper af hvid smeltet bauxite alumina anvendes til en række industrielle applikationer. - Det er nyttigt først at opnå den ønskede overfladebehandling. Virksomheder som Datong ved, at forskellige projekter vil have forskellige finisher. Ved at bruge den rigtige kornstørrelse, kan arbejdere sikre sig, at de ikke kun fjerner den rette mængde materiale, men også opnår det ønskede udseende for det pågældende materiale. For eksempel vil en finere kornstørrelse give en blank finish, mens grovere korn er mere strukturerede og matte.

Konklusion

Endelig kan sikkerheden også forbedres ved valg af passende kornstørrelse. Med effektivt korn er forekomsten af brud eller beskadigelse af værktøjer lav. Det er vigtigt, fordi beskadigede værktøjer kan forårsage ulykker på arbejdspladsen. Datong er dedikeret til sikkerhed, så dets produkter gør arbejdspladsen sikrere. Fordele ved at anvende forskellige kornstørrelser af hvid smeltet Bubble Alumina er meget store. De bidrager til den rigtige finish og sparer tid og materiale samt øger sikkerheden på arbejdspladsen.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ