उच्च गुणवत्ता वाला अग्नि-प्रतिरोधी पदार्थ भट्टियों को ठीक से चलाने के लिए आवश्यक है। आपकी भट्टी के लिए सही अग्नि-प्रतिरोधी पदार्थ का चयन करना उसके प्रदर्शन और आयु के लिए आवश्यक है। डाटोंग के पास उद्योग उपयोग की किसी भी आवश्यकता को पूरा करने के लिए उच्च गुणवत्ता वाले अग्नि-प्रतिरोधी उत्पादों की पूर्ण श्रृंखला है। चाहे आप स्टील बनाने के व्यवसाय में हों या ग्लास बना रहे हों, हमारे पास ऐसी अग्नि-प्रतिरोधी सामग्री है जो दुनिया भर के व्यवसायों को आसानी और टिकाऊपन के साथ ऐसा करने में मदद कर सकती है। इस लेख में, हम अपनी भट्टी के लिए अग्नि-प्रतिरोधी पदार्थ चुनने के लिए महत्वपूर्ण बातों पर चर्चा करेंगे। लेकिन पहले: डाटोंग क्यों?

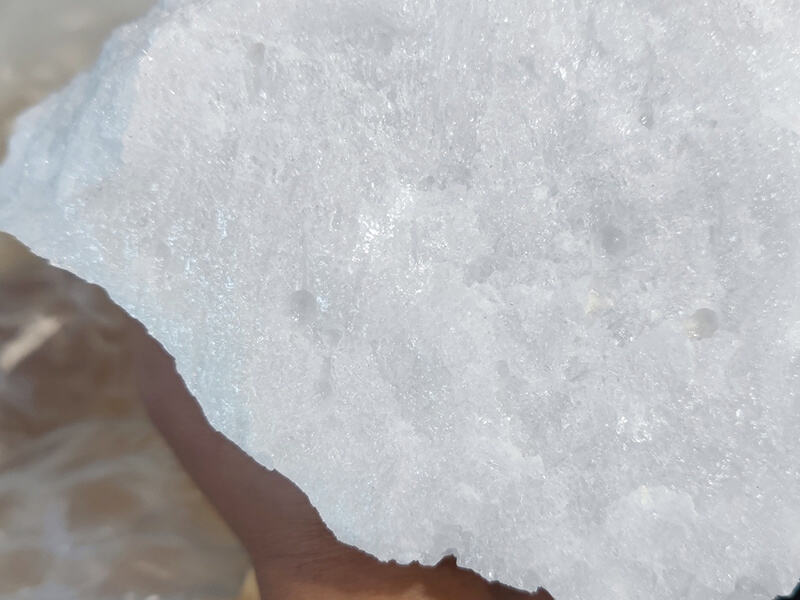

जब आप अपने भट्ठी के लिए रेफ्रैक्टरी का चयन कर रहे हों, तो कुछ बातों को ध्यान में रखना चाहिए। भट्ठी के प्रकार, तापमान, वातावरण, शुद्धता और कई अन्य आवश्यकताओं पर आपके अनुप्रयोग के लिए सबसे उपयुक्त रेफ्रैक्टरी सामग्री निर्धारित होती है। दतोंग विभिन्न रेफ्रैक्टरी उत्पाद प्रदान करता है, जिसमें फायरक्ले-आधारित और सिलिका-आधारित, एल्युमीना-आधारित के साथ-साथ ज़िरकोनिया-आधारित आदि शामिल हैं, जिनका उपयोग विभिन्न अनुप्रयोगों के लिए किया जाता है। हमारे कर्मचारी आपकी विशिष्ट आवश्यकताओं का आकलन करने और यह निर्धारित करने में आपकी सहायता कर सकते हैं कि आपकी भट्ठी के लिए कौन सी रेफ्रैक्टरी उपयुक्त है। जब आप ऊष्मीय चालकता, तापीय आघात प्रतिरोध और क्षरण प्रतिरोध जैसी चीजों पर विचार करते हैं... तो आप उचित रेफ्रैक्टरी सामग्री के साथ यह सुनिश्चित कर सकते हैं कि आपकी भट्ठी सुचारु रूप से और पेशेवर तरीके से काम कर रही है! व्हाइट फ्यूज़ड एलुमिना

दत्तोंग रेफ्रैक्टरी उत्पादों को उनकी उच्च गुणवत्ता और उत्कृष्ट प्रदर्शन के कारण विशिष्ट बनाता है। हमारे कोटिंग्स तापमान की चरम सीमा को संभालने के लिए डिज़ाइन किए गए हैं, रासायनिक तत्वों के प्रति प्रतिरोधी हैं और यांत्रिक आघात के विरुद्ध कवचित हैं। चाहे वह ब्लास्ट फर्नेस, ग्लास टैंक या रासायनिक रिएक्टर के लिए रेफ्रैक्टरी हो, दत्तोंग आपकी मदद कर सकता है! हमारे उत्पादों में उत्कृष्ट ऊष्मा रोधन, बेहतर एंटीकॉरोशन और लंबे सेवा जीवन की विशेषता है। दत्तोंग रेफ्रैक्टरी सामग्री का चयन करने से भट्ठी की ऊर्जा लागत में कमी, रखरखाव लागत में कमी और उपकरणों के जीवन को बढ़ाने में मदद मिल सकती है। अपने उद्योग की आवश्यकताओं के लिए उच्चतम गुणवत्ता वाले रेफ्रैक्टरी विकल्पों के लिए दत्तोंग की ओर देखें।

दातोंग की उच्च एल्युमिना अग्नि-प्रतिरोधी ईंटें, जिनका उपयोग उच्च तापमान वाले थर्मल भट्ठियों में किया जाता है। इन ईंटों को उच्च शुद्धता वाले एल्युमीनियम ऑक्साइड को अन्य कच्चे माल के साथ मिलाकर बनाया जाता है ताकि वे ऊष्मा और रासायनिक हमले के प्रति अभेद्य रहें। इनमें अच्छी तापीय आघात प्रतिरोधकता होती है, जिसका अर्थ है कि तापमान में आए तीव्र परिवर्तनों के कारण ये फटें या टूटें नहीं। इसलिए ये भट्ठी में उपयोग के लिए आदर्श हैं, जहाँ 3000°F के तापमान का सामना करना पड़ सकता है।

एक अन्य विकल्प है Datongrefractory.com सिलिका अग्नि-प्रतिरोधी ईंटें, जो उच्च तापमान का सामना करने में सक्षम हैं। ये सिलिकॉन डाइऑक्साइड आधारित होती हैं जिनमें लगभग 2-6% तक ऊष्मा प्रतिरोधी तंतुओं को मिलाया जाता है, जिससे वे अत्यधिक गर्मी प्रतिरोधी और तापीय चालकता में अच्छी हो जाती हैं। इनका व्यापक रूप से 2300°F से 2600°F तापमान में काम करने वाले गैस दहन भट्ठियों में उपयोग किया जाता है।

भट्ठियों के सेवा जीवन को बढ़ाने के लिए, प्रतिरोधी स्थापना और रखरखाव को सावधानीपूर्वक (संचालन की स्थितियों के अनुसार गुणवत्ता स्तर के साथ) किया जाना चाहिए। सर्वोत्तम परिणामों के लिए, ईंटों को सूखा करने और दरारों को रोकने के लिए पूर्वतापित करें जो हो सकती हैं। एक अन्य बात जिस पर विचार करना चाहिए, भट्ठी के नियमित रखरखाव की है जो किसी भी क्षय या क्षति को देखते हुए किया जाना चाहिए।

साथ ही, भट्ठी में तापमान के उलट-पुलट से बचने के लिए भट्ठी पर फायरिंग कार्यक्रम को नियंत्रण में रखा जाना चाहिए जो प्रतिरोधी को नुकसान पहुंचा सकता है। थर्मल झटकों को रोकने के लिए शीतलन प्रोटोकॉल का भी पालन किया जाना चाहिए। इन सिफारिशों का उपयोग करके, भट्ठियों में प्रतिरोधी का जीवन काफी हद तक बढ़ जाता है, जिससे आपको समय और धन की बचत होती है क्योंकि इसे इतनी बार बदलने की आवश्यकता नहीं पड़ती।

दतोंग के पास 10 मिलियन युआन का बजट है। इसने भट्ठी में अग्नि-प्रतिरोधी, सूक्ष्म पाउडर परीक्षण प्रयोगशाला के साथ-साथ स्कैनिंग इलेक्ट्रॉन सूक्ष्मदर्शी प्रयोगशाला, अनुप्रयोग प्रयोगशाला, उच्च ताप प्रयोगशाला और पायलट आधार के लिए एक कक्ष बनाया है, जिसमें परीक्षण के लिए विभिन्न उपकरणों के 40 से अधिक सेट हैं, जैसे SEM ऊर्जा विश्लेषक, XRF, XRD कण आकार विश्लेषक तथा अन्य कई विश्व-स्तरीय विश्लेषण और परीक्षण उपकरण। तकनीकी केंद्र में 10 से अधिक तकनीकी कर्मचारी हैं जिनमें एक वरिष्ठ इंजीनियर और दो इंजीनियर शामिल हैं, तथा यह वुहान विज्ञान एवं प्रौद्योगिकी विश्वविद्यालय, सिनोस्टील लुओयांग संस्थान, अग्नि-प्रतिरोधी अनुसंधान, लियाओनिंग विज्ञान एवं प्रौद्योगिकी विश्वविद्यालय, झेंगझोउ विश्वविद्यालय और अन्य अनुसंधान संस्थानों के क्षेत्र में अग्नि-प्रतिरोधी के साथ निरंतर संबंध बनाए हुए हैं।

दतोंग ने गुणवत्ता प्रणालियों के लिए ISO9001 प्रमाणन, साथ ही ISO14001 पर्यावरण प्रबंधन प्रणाली प्रमाणन, OHSAS18001 कार्यस्थल स्वास्थ्य एवं सुरक्षा प्रबंधन प्रणाली प्रमाणन प्राप्त किया है, और एक राष्ट्रीय उच्च-प्रौद्योगिकी उद्यम है, जिसका सफलतापूर्वक फर्नेस स्टॉक कोड: 836236 में लिस्टिंग हुई है। यह अब उच्च-गुणवत्ता वाली एल्युमीनियम-आधारित सामग्री का सबसे बड़ा और सर्वांगीण स्रोत है। प्रत्येक टैंक का हाइड्रोलिक परीक्षण, रेडियोग्राफी परीक्षण और वायुरोधी परीक्षण आदि द्वारा निरीक्षण किया जाता है। दुनिया भर की सबसे उन्नत उत्पादन मशीनें यह सुनिश्चित करती हैं कि उत्पादन के प्रत्येक चरण में कठोर गुणवत्ता नियंत्रण बनाए रखा जाए। प्रत्येक छोटी से छोटी बात का हमें निकटता से ध्यान रखने की आवश्यकता होती है, और प्रत्येक कार्य कार्यबल का एक महत्वपूर्ण हिस्सा है।

हम भट्ठी में अग्निरोधी उच्च-ग्रेड कच्चे माल, कई मूल्यवान वस्तुओं और सेवाओं के साथ-साथ अपने ग्राहकों के साथ आगे बढ़ रहे हैं। इसी तरह, उच्च मानक के अतिरिक्त समान उत्पादों के साथ ग्राहकों की बेहतर सेवा करने के लिए, डाटोंग कंपनी अपने सभी भागीदारों के साथ जीत-जीत के वातावरण का निर्माण करने को तैयार है!

कैफेंग डाटोंग रेफ्रैक्टरीज कंपनी लिमिटेड 2008 में स्थापित की गई थी, और यह एक निजी संयुक्त स्टॉक कंपनी है जो भट्ठी में अग्निरोधी में स्थित है जो उच्च-गुणवत्ता वाली अग्निरोधी सामग्री के निर्माण के साथ-साथ विकास और बिक्री में विशेषज्ञता रखती है।

कॉपीराइट © कैफ़ेंग डाटोंग रेफ्रैक्टरीज़ कंपनी, लिमिटेड. सभी अधिकार सुरक्षित। - गोपनीयता नीति-ब्लॉग