Un refrattario di alta qualità è essenziale per il corretto funzionamento dei forni. La selezione del refrattario adatto alla propria fucina è fondamentale per le prestazioni e la durata nel tempo. Datong offre una gamma completa di prodotti refrattari di alta qualità, in grado di soddisfare le esigenze di qualsiasi applicazione industriale. Che siate nel settore della produzione dell'acciaio o della creazione del vetro, disponiamo di materiali refrattari che possono aiutare aziende in tutto il mondo a operare con facilità e durabilità. In questo documento tratteremo le considerazioni importanti nella scelta del refrattario per il proprio forno. Ma prima: perché scegliere Datong?

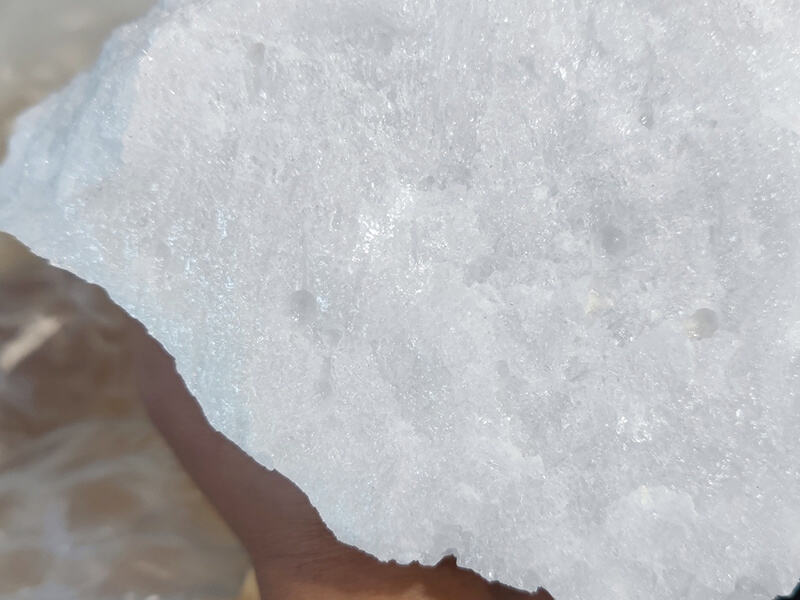

Quando scegliete un refrattario per il vostro forno, ci sono alcuni aspetti da considerare. La scelta del forno, della temperatura, dell'atmosfera, della purezza e di molti altri requisiti determinerà il materiale refrattario più adatto alla vostra applicazione. Datong offre una varietà di prodotti refrattari, sia a base di argilla refrattaria che a base di silice, di allumina e di zirconia, ecc., utilizzati per diverse applicazioni. Il nostro personale può aiutarvi a valutare le vostre esigenze specifiche e a determinare quale refrattario sia più adatto al vostro forno. Quando prendete in considerazione fattori come conducibilità termica, resistenza agli shock termici e resistenza all'erosione... potete garantire che il vostro forno funzioni in modo efficiente e professionale con il materiale refrattario appropriato! Alumina Fusa Bianca

Ciò che rende unici i prodotti refrattari Datong è la loro elevata qualità e prestazioni eccellenti. I nostri rivestimenti sono progettati per resistere a temperature estreme, all'esposizione chimica e agli attacchi meccanici. Che si tratti di materiali refrattari per un altoforno, una vasca per vetro o un reattore chimico, Datong può aiutare! I nostri prodotti offrono un'ottima isolamento termico, una migliore resistenza alla corrosione e una lunga durata. La scelta dei materiali refrattari Datong può contribuire a ridurre i costi energetici del forno, abbassare i costi di manutenzione ed estendere la vita delle attrezzature. Rivolgetevi a Datong per le opzioni refrattarie di massima qualità in base alle esigenze del vostro settore.

I mattoni refrattari in allumina ad alta resistenza di Datong, utilizzati nei forni termici ad alta temperatura. Questi mattoni sono prodotti mescolando ossido di alluminio ad alta purezza con altri materiali grezzi, rendendoli impermeabili al calore e agli attacchi chimici. Hanno un'ottima resistenza ai shock termici, il che significa che non si crepano o rompono a causa di bruschi cambiamenti di temperatura. Ciò li rende perfetti per l'uso nei forni, dove possono verificarsi temperature fino a 3000°F.

Un'altra scelta disponibile su Datongrefractory.com sono i mattoni refrattari in silice, che sono anch'essi in grado di resistere ad alte temperature. Sono a base di biossido di silicio con un aggiunta di circa dal 2% al 6% di fibre resistenti al calore, il che li rende altamente resistenti al calore e dotati di buona conducibilità termica. Vengono ampiamente utilizzati nei forni a combustione di gas che operano a temperature comprese tra 2300°F e 2600°F.

Per aumentare la durata dei forni, l'installazione e la manutenzione dei materiali refrattari devono essere eseguite con attenzione (con un livello di qualità adeguato alle condizioni operative). Per ottenere i migliori risultati, preriscaldare i mattoni per asciugarli ed evitare crepe che potrebbero verificarsi. Un altro aspetto da considerare è la manutenzione regolare delle usure e dei danni del forno, se presenti.

Inoltre, il programma di cottura del forno deve essere mantenuto sotto controllo per evitare brusche variazioni di temperatura che potrebbero danneggiare il materiale refrattari. Anche le procedure di raffreddamento devono essere rispettate per prevenire shock termici. Applicando questi suggerimenti, la vita dei materiali refrattari nei forni si allunga in modo significativo, consentendo di risparmiare tempo e denaro grazie a sostituzioni meno frequenti.

Datong ha un budget di 10 milioni di yuan. Ha costruito un forno refrattario, un laboratorio per test di micro polvere e una stanza per il microscopio elettronico a scansione, un laboratorio applicativo, un laboratorio ad alta temperatura e una base pilota, dotati di più di 40 apparecchiature di prova tra cui spettrometro energetico SEM, XRF, analizzatore della dimensione delle particelle XRD e molte altre attrezzature di analisi e prova di livello mondiale. Il centro tecnico ospita più di 10 addetti tecnici, tra cui un ingegnere senior e due ingegneri, e mantiene una collaborazione continuativa con l'Università di Scienza e Tecnologia di Wuhan, l'Istituto Sinosteel di Luoyang per la ricerca sui refrattari, l'Università di Scienza e Tecnologia del Liaoning, l'Università di Zhengzhou e altri istituti di ricerca nel campo dei refrattari.

Datong ha ottenuto la certificazione ISO 9001 per i sistemi di qualità, nonché la certificazione del sistema di gestione ambientale ISO 14001 e la certificazione del sistema di gestione della salute e sicurezza sul lavoro OHSAS 18001, ed è un'impresa nazionale ad alta tecnologia, quotata con successo nel settore dei materiali refrattari con codice azionario: 836236. È ora la fonte più grande e completa di materiali alluminosi di alta qualità. Ogni serbatoio viene sottoposto a prova idraulica, prova radiografica e prova di tenuta all'aria, ecc. Le macchine produttive più avanzate a livello globale garantiscono un rigoroso controllo della qualità in ogni fase della produzione. Ogni singolo dettaglio richiede la nostra massima attenzione, e ogni azione rappresenta una parte fondamentale del lavoro del personale.

Utilizziamo materiali refrattari in forni con materie prime di alta qualità, una varietà di articoli e servizi pregiati, progredendo insieme ai nostri clienti. Allo stesso modo, al fine di servire meglio i clienti fornendo prodotti simili aggiuntivi di alto livello, la Datong Company è disposta a creare un ambiente di reciproco vantaggio con tutti i suoi partner!

Kaifeng Datong Refractories Co., Ltd. è stata fondata nel 2008 ed è un'azienda privata a partecipazione azionaria situata in un'area specializzata nei materiali refrattari per forni, che opera nella produzione, nello sviluppo e nella vendita di materiali refrattari di alta qualità.

Copyright © Kaifeng Datong Refractories Co., Ltd. Tutti i diritti riservati. - Informativa sulla privacy-Blog