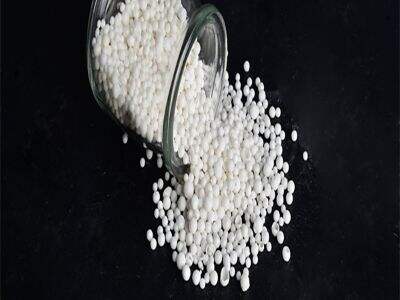

Mullite and zirconia they are two main stuff used to make refractories. Refractories is special products that can stand super high heat without getting destroy. They use in furnaces, kilns, or reactors and things like that. Mullite come from clay mostly, it have nice strength and stay stable when hot. Zirconia on other hand made from zirconium, famous because resist thermal shock very good. Both got advantages but also some bad points. Knowing difference help companies pick right one depend on what they need and how much money they have.

Good Mullite and Zirconia Refractories in Wholesale

If your looking for quality mullite and zirconia refractories, Datong is good place start with. We got lots of choice at wholesale price. Buy big amount save money especially for large project. Our stuff get tested so they work fine in tough condition. When buy refractories not only price matter, quality also very important. You want material last long and not fail in critical time. Datong give detail info about product, so you can decide better. Visit website or talk our sales team for more. We help find correct one whether small company or big factory.

Benefit Using Mullite Instead Zirconia in Refractories

Mullite refractories often cheaper choice than zirconia for many use. Because mullite usually cost less to make. So when buy lots, total price become much lower. For exemple building furnace with mullite save cash for other part of project. Also mullite have decent thermal shock resistance, so good for high temp without change often. Another thing mullite lighter compare zirconia, easy handle and put in place. This reduce labor cost cause worker move it faster. But remember mullite cheaper mostly, zirconia better perform in some very extreme case. So choice depend what temperature and condition refractories face. Every case different, Datong can advice which one best for customer need.

Quality

When search best wholesale price for mullite and zirconia, need know where look. Mullite and fused zirconia mullite special material for make refractories, heat resist product use in kiln furnace etc. Start with local supplier focus on industrial or building stuff. They often give good price cause buy bulk. For better deal online market help alot. Site sell industrial material have competition price and discount for big order. Also good check trade show or exhibition about manufacturing. There connect supplier give special rate for business buy large. Datong our company known for quality refractories both mullite zirconia. We try give best price and product always. When hunt deal wise compare from few supplier and check shipping cost cause it add up.

Application

When use mullite and zirconia some common problem need think. Both have strong and weak side, know them help choose right for need. Mullite good at thermal shock resist, handle quick temp change no crack. But less durable than alumina and zirconia if very high heat or corrosive place. Zirconia stronger withstand higher temp, popular for extreme. But cost more, so keep in mind for budget. Also how process and install matter. Mullite easier work with good if manual job lots. But wrong install cause trouble later. Zirconia durable more but need special know how install proper. At Datong we say always follow guide from maker to avoid issue. Last think about environment use. Both react different to chemical and condition so consider project specific. By know these usage issue can pick better between mullite zirconia suit your requirement.

Conclusion

Latest trend in fused alumina zirconia interesting develop help many industry. Big one is make more eco friendly product. Company like Datong work develop refractories lower impact environment. Means produce use less energy reduce waste. Another trend improve performance both mullite zirconia. Researcher find new way make stronger durable. For example add some additive enhance resist high temp and wear. Also nanotechnology get popular in refractory field. This tech make material better property in small scale for efficient product. There growing interest customize refractory for specific industry. Business want product fit unique need like metal production glass making other high temp. By tailor mullite zirconia different requirement company offer better perform longer last.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ