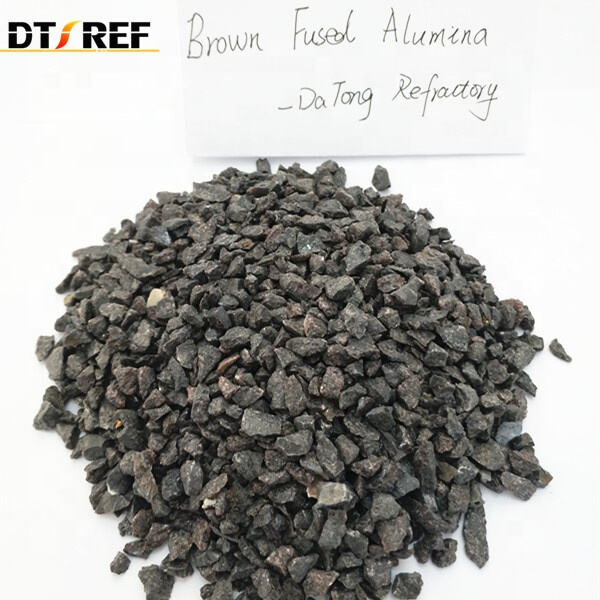

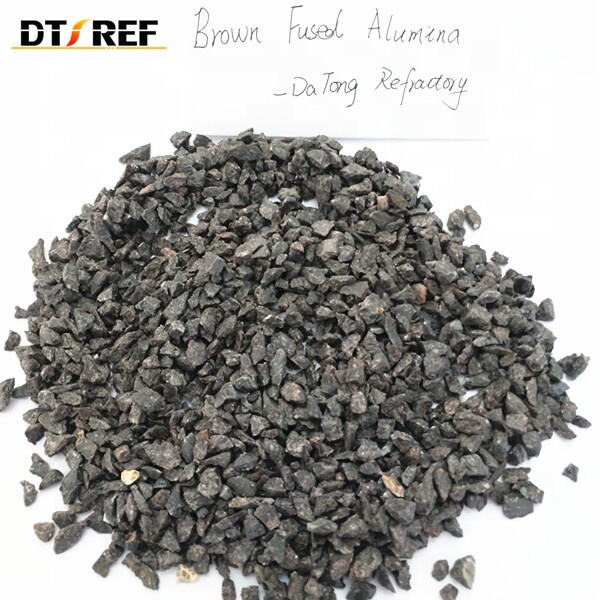

Brown alumina is a material with many industrial applications. Mined from the ground, bauxite is a naturally occurring compound that can be used in every day products. The brown alumina is also know as Brown fused seinna. It resembles sand, and is brown making it easy to identify. In this blog, we would like to introduce the performance of brown alumina, learning what kind of products it will she use for and why is that a good material while using metal works including ceramic. But, not to worry, we come afresh with a deeper dive into its multiple use-cases and the positives for all stakeholders.

This alumina is widely used in many industries. By nature, it is very strong and can stand up to high heat and as such is excellent for creating tools or anything else that needs some strength. Brown aluminum is the material can use for cutting tools, grinding wheels and some special powders to polish or sand on metal or wood surface. Brown Alumina is popular among factories for that very reason - it works and its relatively fairly priced. That versatility also makes it a popular choice for manufacturers of industrial products because its design can be adapted - even in the most elemental and leading-edge applications.

Below are several reasons why those people select brown alumina. Well it is for one of the big reasons-it is very difficult and challenging. This makes it a very high density item that is not easy to break, and will last as long as you need. For starters, each piece of brown alumina is the same size and It helps to ensure a smooth surface on different materials. This consistency is important especially for metals and ceramics that can be difficult to work with, such as it the case during grinding or polishing of these materials. In general, it is considered the top choice for a number of uses due to its dependability and power.

In the ceramic industry, one of the most important positions Brown alumina plays. That makes it ideal for things like bricks and tiles that need to withstand high heat. So, anything sold in the open air is constantly subjected to high heat/cold and required to have toughness. The also contributes to increased strength in ceramic materials and together with the is a method advantageous to cracking of ceramics. Brown Fused Alumina makes the ceramics have good strength and toughness to bear regular abrasion, hence making this material more reliable for various applications.

Abrasive Wear in Brown AluminaBrown alumina has several unique characteristics not found anywhere else. To begin with, it is effective against high temperatures hence good for applications requiring heat resistance. Many industrial processes require this high melting point. Second, it is virtually unbendable which makes the Grinder hard; a good choice for all surface work. Moreover, brown alumina is not readily plagued by rust and thus also used in harsh conditions where most other materials would fail. Finally, it has a small thermal expansion factor (i.e., it does not expand with heat and shrink when cold). This feature is pivotal for precision in different applications.

Brown alumina is mainly used to prepare brown corundum, and it also helps metal making many a ways. It is used to produce cutting tools and abrasive wheels for shaping metal pieces correctly. It withstands high temperatures which means if other machines are operating, it will prevent them from getting damaged. This heat resistance is necessary within the metal fabrication process. Brown alumina is also used to provide a flat surface and smooth finish on metal componentrac particles. Critical because a smooth surface is vitally important to allow parts granularity during alignment, when fit together in the final product.

Kaifeng Datong Refractories Co., Ltd. was established in 2008 and is a brown alumina joint stock company located in Henan province. It is specialized in the production and distribution of high-quality refractory materials.

Datong is a highly-tech national company that has been able to pass the ls0900l quality certification system and also the is014001 certificate for the environmental management system as well as the brown alumina accreditation for occupational health and safety. It was first listed on the 7th of April 2016 under the stock code 836236. Nowadays, it has become the largest and most comprehensive quality aluminum-based refractory raw base. Each tank is scrutinized with hydraulic test, radiography test, and air tight test, etc. The most sophisticated production equipment in the world assure strict quality control at each stage of production. We pay attention to every detail, and each small action is an integral part of our workforce.

We brown alumina high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

Datong has invested brown alumina in the construction of the chemical analysis laboratory, micro powder testing room as well as a scanning electron microscope high-temperature laboratory for applications as well as a pilot base. There are over 40 sets of of testing equipment including SEM energy spectrumrometer XRD XRF laser size analyzer, along with other world class testing and analysis equipments. The center employs over 10 scientists and engineers comprising a senior engineer and two engineers. It also maintains a close cooperation with Wuhan University of Science and Technology and Sinosteel-Luoyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog