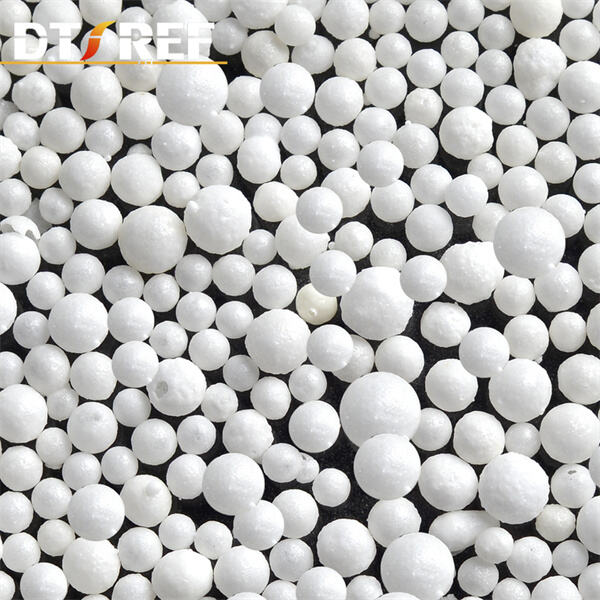

High alumina balls are a special type of ball which makes it easy and convenient for both the companies to do their work in an effective way. These balls are found mostly in places like factories, and laboratories ect where humans engages with making of things. High alumina balls are made of a tough material like hard rock called as Alumina. These balls are significant as they provide great features which play their role in different use cases across multiple industries.

The high alumina balls are playing a crucial role in serving industries with vast applications for various jobs depending on different sizes packages. The best part of these balls is, they will produce the materials which can withstand extreme temperature conditions. Refractory materials [1]: these are the materials used in times of high heat; for example, ovens and furnaces which need to be heated up before it is turned off. It improves the working efficiency of refractory materials and makes them stronger, more durable products. That translates to materials companies can trust for long-lasting performance.

Some firms work in exceptionally hard settings which might have a great deal of chemicals or really high and low temperatures. These are a real match for these bad diamonds which most easily strategize in this case where is broken and solved the high alumina balls. They are likewise resistant to chemical damage, so that they do not be affected by the chemicals which usually come into contact with these insulation materials. This strength makes it possible for companies to produce high alumina balls and make strong machines or devices made out of these. The industries that rely on this equipment to keep their operation going, binds them really tight.

A catalyst is something that makes reactions go faster and helps them to happen more easily. The complexity of a trickle-down environmental aid is vast as the buyers for catalyst may be, many are enthralled with yet another technology whose cost can only do on one direction. Since High Alumina Balls Are Very Strong, And Neither Do These React With Any Of The Materials They Make A Good Catalyst. In practice, this allows companies using high alumina balls to form catalysts that are both more efficient in their operation and longer-lived. These improved products and processes allow companies to get better results in the work they do by using high alumina balls.

Companies are always looking to mass produce parts quickly and inexpensively in order to meet demand. The high alumina balls allow them to do so in the manner of manufacturing their products. O ne of the strong qualities about the high alumina balls is that it could be performed quickly into custom design - no matter what genuine jobs entail. It helps with the production process, making it smoother and more efficient. Furthermore, they have a very high breaking strength and can be used in machines that work at extremely fast speeds. The strength and versatility make them integral to a wide array of manufacturing processes.

There are a lot of uses for high alumina balls in the many different industries because high alumina is very effective. These are ideal for applications that need materials to be tough and heat resistant. Industries where high alumina balls are used Steel-making | Chemical production | Oil refining and Electronics. They are also valuable in aerospace operations where materials have to sustain very high temperature and other conditions. Their use is growing exponentially in various sectors as more and more enterprises realize the advantages of high alumina balls, making them popular.

Kaifeng Datong Refractories high alumina ball was founded in 2008 and is a private joint-stock corporation located in Henan province. It specializes in the production and development of high-quality refractory material.

high alumina ball has invested approximately 10 million yuan, and has constructed a chemical analysis laboratory, micro powder testing laboratory, scanning electron microscope room lab, application laboratory, high temperature laboratory and a pilot base with more than 40 different testing instruments, including SEM, energy spectrometer, Laser particle size analyzer as well as many other world-class analysis and testing equipments. The center employs more than 10 scientists and engineers including a senior engineer and two other engineers. It also maintains close partnership with Wuhan University of Science and Technology and sinosteel Luoyang Institute of Refractories Research, University of Science and Technology Liaoning and Zhengzhou University.

Since the beginning of high alumina ball Datong Refractories Co., Ltd in 2008 as subsidiary corporation of Hecheng. Has been specializing in alumina-based refractory raw materials and related products on the global market. We're dedicated to supplying customers with top-quality and reliable products. To be the first-class service provider of high-grade raw materials for refractory, we provide high-quality services and products that grow along with our customers. In the meantime. Datong Company wants to create a win-win partnership with all its partners in order for it to provide its customers with better and offer them top quality products.

Datong has been awarded high alumina ball quality system certification, is014001 environmental management system certification OHSAS1800 occupational and safety management system certification, is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code 836236. Nowadays, it has become the largest and most complete quality aluminum-based refractory raw material base. Each tank is scrutinized by means of a hydraulic test and radiography test, and air tight test, etc. The most advanced production machines in the world guarantee strict quality control at every stage of production. We pay close attention to every detail, and every little thing is a part of our workforce.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog