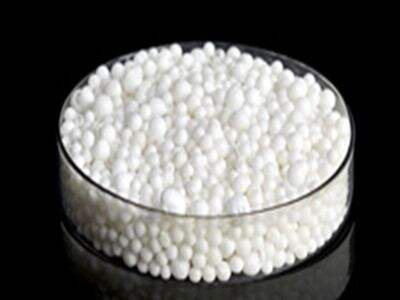

For smooth finish and accurate measurements it is regarded as the best option for professional to excel in the world of precision grinding. Why White Corundum is so unique? Here's five of the top reasons that make it the best option for precision grinding.

Strong and Durable:

Because of its hardness and strength, white corundum tends to be used as grinding material. Its hardness enables it to cut through material while keeping itself sharp for a long period of time. Because of this, employees are able to depend on White Corundum to give them the best results, even when using difficult materials.

Even Grain Size:

One thing with White Corundum is that it has a very uniform grain size. This also aids in accurate material removal so it is easier for workers to achieve the desired finish. There are no bumps or “low spots” with White Corundum – it simply provides a smooth finish every time.

Clean and Pure:

Grit involves having to clean during grinding. White Corundum is extremely pure with low impurities, it is very suitable for clean grinding work. Use its pure quality is no unwanted material in the end product, and low impurities result in smooth, effective grinding.

Cools Well:

One important thing to consider when precision grinding calcined alumina is to keep it cool and not allow the material to overheat. White Corundum's high heat conductivity helps it to distribute the heat out quickly and keep the abrasive and workpiece cool during grinding. It also helps optimize the process and may prolong the life of the abrasive, making it a smart choice for workers.

Used in Most Industries

Last but not least, with the highest quality White and brown corundum grinding wheel brown aluminium oxide, it can be employed in precision grinding. Its hardness, even grain size, purity, coolness retention, and flexibility enable it to achieve fine finishes and accurate measurements in numerous industries. When precision grinding comes into play, White Corundum is the answer to any expert who desires to attain outstanding results.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ