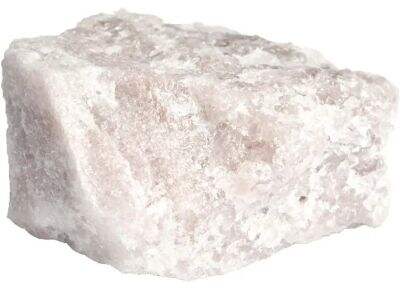

Fused Spinel Is an Essential Element in Modifying the Performance of Steel-Making Refractories

It provides a variety of product advantages in economy, steel quality, furnace life, heat resistance and cost savings. Kaifeng Datong Refractories knows how important fused spinel is, especially in the steelmaking sector. So, let’s explore how fused spinel is disrupting steelmaking as we know it.

How Fused Spinel Improves the Efficiency of Steelmaking Furnaces

Reactive space Multiple Space Systems Payload Facility (MSSPF) Fused Spinel is a value-added product that enhances steelmaking furnaces performance. It can resistant to high temperature and difficult charging condition by using fused spinel in the hearth of the furnace. And in doing so it helps regulate the temperature of a furnace which then allows for smooth and effective steel manufacturing. Fused spinel’s high resistance against thermal shock also prevents the occurrence of rapidly changing temperatures and extending the life time of furnace lining, thus minimizing downtime due to maintenance.

Enhancing Steel Quality with Fused Spinel Technology

The use of fused spinel technology in steel making furnaces can contribute to a substantial improvement in quality of the steel being made. This superb corrosion resistance capability of fused spinel precludes any form of contamination with the steel during production. The product yielded from this process is steel with better mechanical characteristics and improved performance. By affecting the steel’s purity and cleanliness, fused spinel enables manufacturers to meet strict quality standards and customer needs.

Improving Furnace Life Using Fused Spinel

Fused spinel, with its highly resistance to wear, is therefore a great choice for increasing the lifetime of steelmaking furnaces. Results show that the refractory lining endures well under harsh conditions thanks to the excellent wear resistance of fused spinel. This decreases the need for furnace repairs and replacements, which in turn also reduces maintenance costs and extends the life of the furnace. Steel companies can now rely on durable, efficient equipment for their operations with fused spinel technology.

Fused Spinel Helps to Enhance Heat Resistance of Steelmaking Furnaces

One of the most important attributes of fused spinel in steel making furnaces is its outstanding heat resistance performance. Moreover, fused spinel is used as a high temperature refractory lining of furnaces since it does not melt under very high temperatures. Such a high heat resistance contributes to the ability of the furnace to function at such desired temperatures for lengthy periods, and steel production being economical. Moreover, the thermal resistance of gray spinel reduces the possibility of thermal fatigue failure and cracking, thereby increasing overall performance and reliability of the furnace.

Cost Reduction by the Development of Fused Spinel

Use of Fused Spinel in Steel Making Furnace is more and more popular, which can save the amount of industrial fuel largely. The durability and life span of the fused spinel means less maintenance and repair which translates into lower costs over time. By reducing off spec and maximizing upon operations, the fused spinel technology enables you to optimize production process and overall cost effectiveness. In addition to its excellent efficiency, fused spinel helps produce higher quality steel, thereby enhancing the value and marketability of finished products.

fused spinel technology is a key to maximizing the performance of steelmaking vessels. Increasing efficiency, increasing the quality of steel, increasing lifespan and heat resistance are a few ways in which magnesia spinel provides cost-saving operational advantages. at the forefront of converting fused spinel into a value adding product for use in the steel industry creating new possibilities and opportunities to increase productivity, reduce cost and improve quality in your operations. We pride our self on the quality of our products and focus in its production make us one of the leaders in the field of modern technology for the steel industry.

Table of Contents

- Fused Spinel Is an Essential Element in Modifying the Performance of Steel-Making Refractories

- How Fused Spinel Improves the Efficiency of Steelmaking Furnaces

- Enhancing Steel Quality with Fused Spinel Technology

- Improving Furnace Life Using Fused Spinel

- Fused Spinel Helps to Enhance Heat Resistance of Steelmaking Furnaces

- Cost Reduction by the Development of Fused Spinel

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ