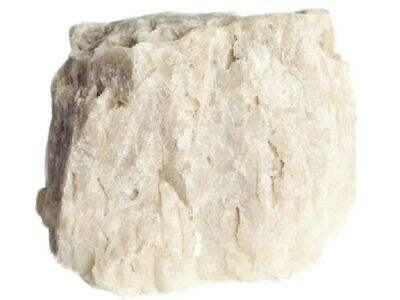

Fused spinel is a type of material used in a variety of industries

Manufacturing electronics and ceramics, for instance. One Intended Use It's important to be familiar with the purity of the fused spinel because it impacts how the material will perform. The higher the purity, the better the quality of fused spinel. At Datong, we are committed to high-quality fused spinel featuring the best purities for the best results in your product.

Importance of High Purity of Fused Spinel

Fused spinel is one of those materials where purity counts. The purer the spinel, the better it is. Impurities can lead to problems such as making the material less stable, or altering how it appears. At Datong we definitely strive to get our fused spinel as pure as possible. This gives us, and our customers, confidence that we’re getting the very best product for the job.

The Relationship Between Impurity Concentrations and Properties of Fused Spinel

Fused spinel is synonymous with purity and high quality. If the level of purity is high, so is the quality. This means, whatever the spinel is used for, the spinel will perform better. Low purity may cause the material to not function as intended, which for companies and their products can be a big headache.

The Standards to Judge High-Quality Fused Spinel

There are several things that you must consider to know if fused spinel is high quality. One of them is the level of purity. Other factors include things like appearance of the spinel and its physical properties — how hard it is, for example, and how it responds to heat. At Datong, we review all of these items to ensure our fused magnesia spinel is as good as it can get.

The Importance of Purity Levels for Improved Performance of Fused Spinel Products

The higher the purity, the better the fused spinel work. High-purity spinel, for instance, can be useful in electronics to produce more efficient and reliable devices. In ceramics, it can give the end products more strength and durability. That’s why at Datong, we strive to have a high purity level of our fused spinel to improve the performance of products it is used in.

The effect of purity level on the overall value and longevity of fused spinel product

The purity level has a great effect on the quality and performance of the fuse spinel. High-purity spinel lasts longer and performs better, and that’s better for both manufacturers and users. It translates into less repair or replacement over time, and can save money in the long run. And that’s why purity levels matter – why we make them such a focus here at Datong.

Table of Contents

- Fused spinel is a type of material used in a variety of industries

- Importance of High Purity of Fused Spinel

- The Relationship Between Impurity Concentrations and Properties of Fused Spinel

- The Standards to Judge High-Quality Fused Spinel

- The Importance of Purity Levels for Improved Performance of Fused Spinel Products

- The effect of purity level on the overall value and longevity of fused spinel product

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID LT

LT SR

SR SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA CY

CY AZ

AZ LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ