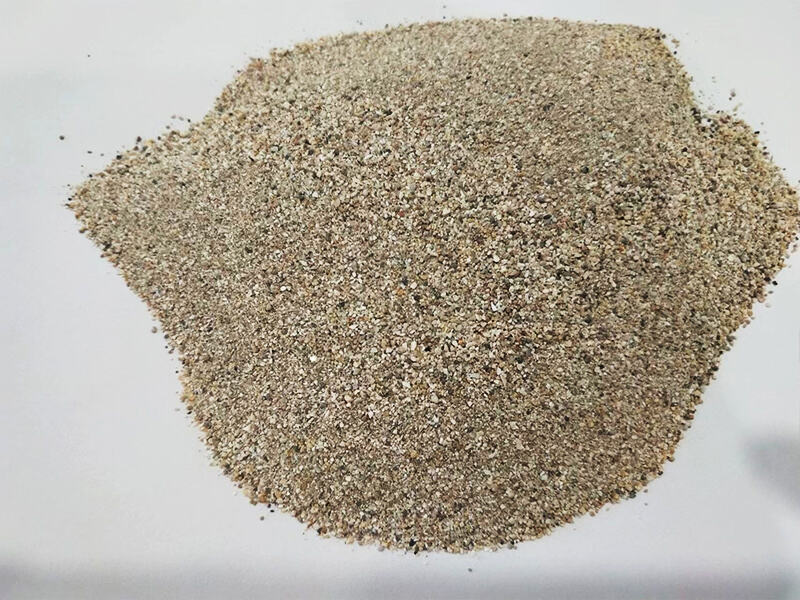

Datong is a proud Bubble Alumina black silicon carbide manufacturer with high quality for all kinds of building materials and industry applications. Black Silicon Carbide has high hardness and sharpness but is more brittle than green silicon carbide. Our black silicon carbide abrasive powder is manufactured specifically for the applications as a surface preparant such as grinding, lapping, and polishing. Fused alumina magnesia spinel is another important material used in the refractory industry.

Industrial Applications of Bubble Alumina Black Silicon Carbide's production process involves the use of an electric resistance type furnace with quartz sand and petroleum coke. Calcined α-AL₂O₃ Powder is another material commonly used in the production of refractories.

Black silicon Carbide is of high hardness, brittleness, and sharpness, and has excellent grinding ability; it is one most commonly used abrasive materials not only on the production of focal treatment (refractory industry) but also in other lines. It is widely used in metalworking, woodworking, ceramics, and other industrial manufacturing applications cutting, grinding, sanding, and polishing. The angular shape and hardness of black silicon carbide also make it an extremely aggressive media for removing material—making it a perfect choice for your first step in rock polishing. Whether it's for cutting, grinding, or sanding abrasive materials and surfaces, black silicon carbide is a great choice. Calcined α-AL₂O₃ Powder is another material commonly used in the production of refractories.

At Datong, we are proudly committed to the quality and consistency of our black silicon carbide products. Our production process is to first choose raw material standards, second control a highly strict quality standard, and then resulting in effective that deliver trust. If you have any requirement for the product. Our black silicon carbide products have high hardness, high elasticity modulus, sharp edges, and stable chemical behavior, and can be used to process ship, metal structure, and coupling piece as well as for the wiring gutter. No matter you are doing blasting work or starting a new abrasive project, Datong black silicon carbide is the common choice for blast media.

Datong's black silicon carbide is perfect for bulk purchasers in search of quality abrasives at reasonable prices. Our goods are built to the highest standards of construction in terms of performance and reliability at an affordable price. With Datong as your supplier of black silicon carbide, you have the competitive edge that will help your business grow. Our black silicon carbide will be the perfect material that will offer you many advantages as your cost-effective alternative to other products. We have thousands of tons of inventory with more added every day.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a high-tech black silicon carbide private enterprise in Henan Province, that is specialized in the production, development and sales of high-quality Refractory raw materials as well as related products. After years of development that has never stopped the company now has an annual output of 30.000 tons of high temperature alumina powder 20.000 tons of magnesium aluminum spinel (electric melting melting and sintering) 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina tabular alumina, 8, 000 tons of non-crystalline calcium Aluminate, thirty-three tons of high aluminum cement, and 50, 000 tons of different products that can be castable and shaped.

Datong invested 10 million yuan and built a chemical analysis laboratory which includes a black silicon carbide with a scanning electron microscope application laboratory high temperature laboratory, pilot base and more than 40 sets various tests instruments, such as SEM energy spectrumrometer XRD XRF laser size analyzer and various other world-class test and analysis equipments. The technical center employs more than 10 technical personnel comprising 1 senior engineer and 2 engineers. Datong maintains a close cooperation with Wuhan University of Science and Technology Sinosteel Luoyang Institute of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of the field of refractory.

Since the black silicon carbide of Kaifeng Datong Refractories Co., Ltd in 2008 as a subsidiary company of Hecheng. Has been focused on alumina-based material for refractory and its related products in the international market. We're dedicated to providing customers with high-quality and stable products. To be the world's first-class service provider of high-grade Refractory raw materials, we provide valuable products and services as well as grow alongside customers. While at the same time. Datong Company wants to create an all-win-win partnership with its partners in order for it to serve its customers better and offer them quality products.

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code black silicon carbide. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog