Datong Refralories, a sub-brand of Henan Hecheng Inorganic New Material, is one of the biggest ones that specially producing high grade High Aluminum Refractory material. Our offerings, ranging from reactive/calcined alumina to calcium aluminate cement to Fused alumina magnesia spinel and Sintered alumina magnesia spinel, are proven performers in applications globally. Focused on innovation and committed to quality, EZSpan Conveyor Solutions offers not only a competitive price but also the best in customer service and product value. It also means we are a partner of choice to companies globally, as our focus on quality and sustainability differentiates us within the marketplace.

Datong specializes in the production of integrated kiln lining materials and processing equipment, such as unshaped refractory, insulating bricks for hot blast stove and ceramic cup inductors used in industrial furnaces. Our refractory materials are designed to withstand high temperatures and harsh operating conditions with the goal of overall product life, prolonged mould usability, and reduced replacement costs. With our sophisticated materials applications, we help companies increase energy efficiency, minimize heat loss, and boost overall productivity in a manufacturing process. Datong's high-quality kiln lining makes our customers more efficient and profitable.

At Datong, we share the same value for durability and longevity for your industrial needs. Which is why we want to give you the tools to make your clay projects all that more manageable while also remaining durable and easy to clean with the best coiled kiln liners! Our dense refractory linings are designed to withstand thermal shock, wear, and chemical attack, minimizing the need for costly shutdowns and repairs. With Datong’s durable kiln liners, businesses can avoid downtime, save money on maintenance, and prolong the life of their equipment — adding up to a better bottom line.

Datong can offer tailor-made solutions based on the exact kiln conditions you deal with Features Applications -Customized Kiln Linings We are devoted to Designing and Developing High Performance KILN Lining. 100% customization is what we will do for your needs! Whether it’s a cement plant, steel mill, or glass manufacturing facility, we can take on any challenge and find a lining system that will solve your biggest problems. We design and build the kiln, including all of its components so we can improve on the intricate details in every process through Material Quality, manufacturing techniques, and workmanship right down to the smallest component. Datong’s tailor-made solutions are dedicated to enabling manufacturers and corporations to produce quality products raising the standard of efficiency and productivity.

Eco-Friendly Kiln Lining Options for Sustainable Production Environmentally friendly manufacturing methods have become a critical consideration in nearly every industry.

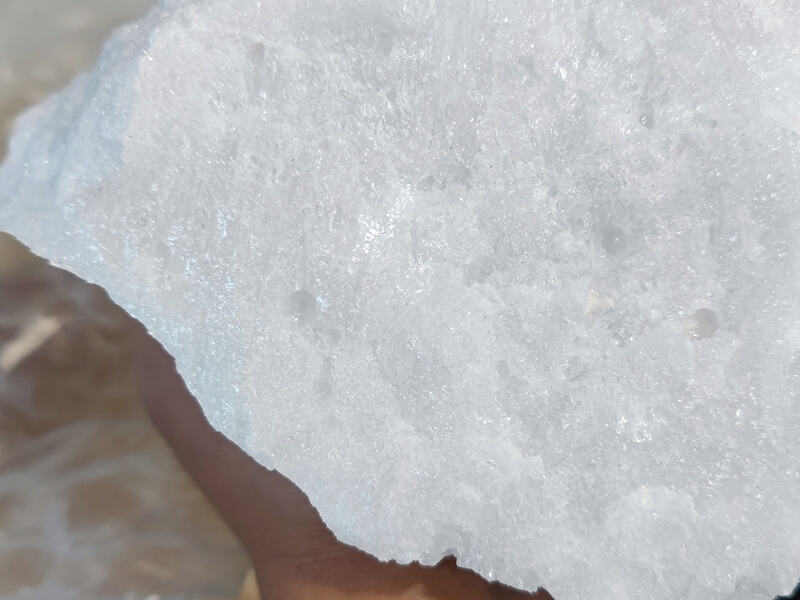

As a responsible manufacturer, Datong endeavours to provide green kiln lining solutions for sustainable production. Our fireclay bricks are made of 100% pure natural minerals and fired in the most sophisticated equipment to control. We manufacture our products under strict quality-controlled conditions with dedicated attention and care. Selecting Datong's green kiln lining services will make a business with less GHG emissions, safeguard natural resources and the environment it serves. By using our sustainable products, businesses can adhere to worldwide sustainability objectives through high operational performance and efficiency.

kiln lining Datong Refractories Co., Ltd was established in 2008. It is a high-tech joint-stock private enterprise in Henan Province, which specializes in the development, production and distribution of premium refractive raw materials and related products. After years of continuous development the company now has an annual output of 30.000 tons of high-temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting the sintering) 10, 000 tons of calcium aluminate, 50, 000 tons white fused alumina, tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate, 30000 tons of high-alcohol cement, and 50, 000 tonnes of various castings and shaped products.

Datong invested 10 million yuan to construct an analytical lab for chemical analysis, micro powder testing room and scanning electron microscope. kiln lining high temperature laboratory with a pilot base and more than 40 sets various tests instruments, such as SEM energy instrument XRD XRF spectrometer laser particle size analyzer, and various other world-class analysis and testing equipments. The center's technical department has more than 10 technical personnel comprising 1 senior engineer and two engineers. Datong maintains a an ongoing relationship with Wuhan University of Science and Technology, sinosteel luoyang insimuie of refractories research University of Science and Technology Liaoning, Zhengzhou University and other research institutes in the field of the field of refractory.

Since the kiln lining of Kaifeng Datong Refractories Co., Ltd in 2008 as a subsidiary company of Hecheng. Has been focused on alumina-based material for refractory and its related products in the international market. We're dedicated to providing customers with high-quality and stable products. To be the world's first-class service provider of high-grade Refractory raw materials, we provide valuable products and services as well as grow alongside customers. While at the same time. Datong Company wants to create an all-win-win partnership with its partners in order for it to serve its customers better and offer them quality products.

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code kiln lining. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog