Refined blast furnace bricks, high temperature resistance and long service life

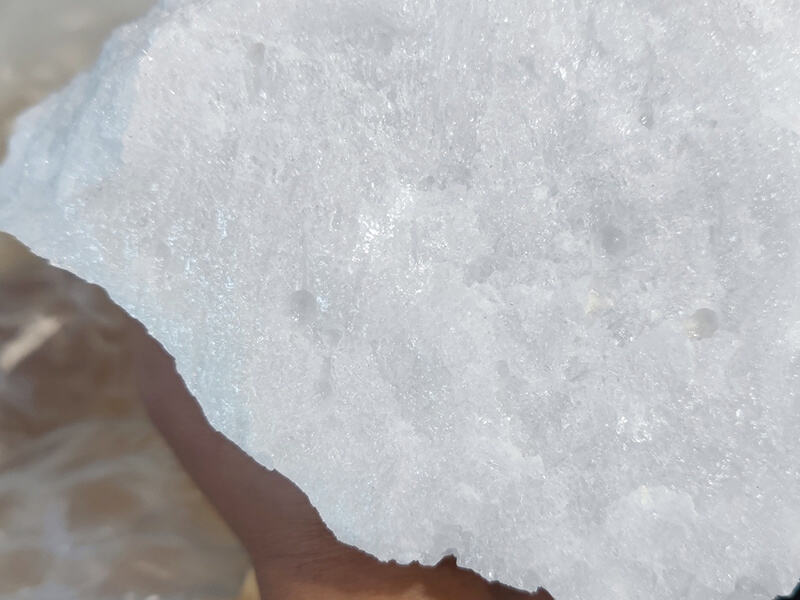

At Datong Refractories we offer the best quality Blast Furnace refractory lining with excellent heat resistance and sturdiness. Our refractory bricks and cooling range are developed with the conditions of the blast furnace in mind. With our well-designed materials and avant-garde techniques, Reactive α-AL₂O₃ Powder we guarantee durable, high performance refractory linings for steel producers aiming to maximize their efficiency and productivity.

The manufacture of steel is a costly and energy-consuming process, which requires highly-effective methods for its implementation. At Datong Refractories, we are familiar with the difficulties steel producers encounter when looking to improve operations and drive down expenses. This is why we provide a variety of tailored solutions for wholesale buyers within the steel market. Blast furnace refractory linings at great value for money. Designed to help steelmakers boost the bottom line. We created our blast furnace type of shapes with efficiency, minimal downtime and cost reduction in mind so that you can maximize your output without compromising quality.

Quality of the lining in blast furnace is particularly important for its performance and durability. At Datong Refractories, it is our mission to provide technically advanced refractory lining solutions for steel makers that can be customized to suit your specific needs. We design our refractory lining systems for efficiency and long life, positioning them to do their best work ripping raw materials apart. Backed by the depth of our industry-leading experience and manufactured with the most innovative technologies and principles, we offer a variety of steel producers long-lasting refractory solutions that guarantee ease of installation, resistance to thermal shock and much more.

Steel manufacturers are under constant energy to reduce downtime and keep maintenance costs low in order to remain competitive. We know how critical to blast furnace operation – reliability and efficiency are at Datong Refractories. That’s why we continually invest in R&D to pioneer new materials and techniques that can decrease your downtime and maintenance costs on steel production. Utilizing the new developments in refractory technology, we provide state of the art solutions that improve performance and extend the life of blast furnace refractory linings.

Each Steel Manufacturer has its own process, but what every one of them have in common are the challenges that need to be confronted for a high performance product. At Datong Refractories, we understand that every wholesale buyer in the steel industry is different. Our professional team cooperate with customers closely to ensure that the products we develop are in compliance with each customer's requirements. Designing a refractory lining for new blast furnace or improving its performance using an existing one, We have solutions that can be tailored to meet customer requirement and derive the best cost-per-ton benefit. “When you do business with Datong Refractories, our teamwork for your stock allows us to offer customized service and the best quality products available in the market; products are designed specifically to increase productivity and efficiency.”

Datong has a budget of 10 million yuan and has built a chemical analysis laboratory and a micro-powder testing laboratory with a scanning electron microscope Application laboratory, high temperature laboratory and pilot base, including more than 40 sets of testing equipment, including SEM and Blast furnace refractory lining, XRD, XRF, laser particle size analyzer, as well as other top-of-the-line analysis and testing equipments. The technical center employs more than 10 technical personnel with 1 senior engineer and two engineers. The center maintains the close collaboration with Wuhan University of Science and Technology Sinosteel Luoyang Insimuie of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of refractory.

Datong has achieved ls0900l certification for quality systems, as well as is014001 environment management system certification OHSAS1800 Blast furnace refractory lining, is a high-tech national enterprise which was able to be listed on April 7, 2016 stock code: 836236. Datong has become the largest and most comprehensive resource of high-quality aluminum-based materials. Every tank is inspected by a hydraulic test, an radiography test, and air tight test, etc. With the most advanced production equipment, strict quality control on each production stage. We pay attention to every single detail, and every single action is an integral part of our team.

Blast furnace refractory lining was created in the year 2008 and is a private joint-stock high-tech company in Henan Province that specializes in the development, production and sale of premium refractive raw materials and related products. Following years of development that has never stopped the company now has an annual output of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting and sintering) and 10, 000 tons of calcium aluminate-based cement, 50, 000 tons white fused alumina tabular alumina. It also has 8, 000 tons of non-crystalline calcium Aluminate, thirty-three tons of high aluminum cement and 50, 000 tons of various castings and shaped products.

We provide high-grade raw materials, high-quality products, and services, as we grow with our customers. While at the same time. to better serve customers offer customers other similar products of a high standard, Datong Company is willing to create and Blast furnace refractory lining relationships with all its partners!

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog