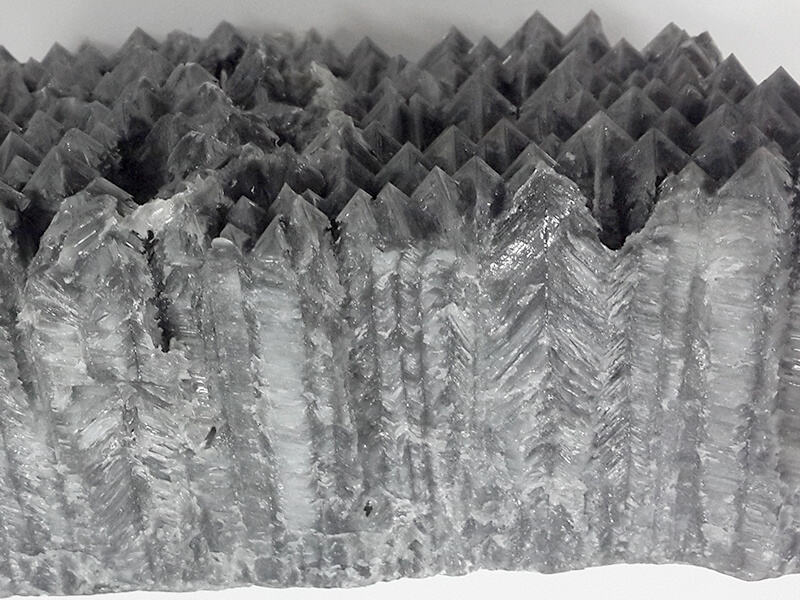

In the industrial sector, there is no doubt about the requirement of high quality Bubble Alumina refractory lining for furnaces. A high integrity refractory interior lining is critical for long term operation at high temperatures and severe environments to substantially increase the operational life cycles of industrial processes. Reactive α-AL₂O₃ Powder is one example of a material known for its high quality and durability.

One of the most important issues for any industry with furnaces is the repair and replacement of their White Fused Alumina refractory lining. The chronic exposure to high temperatures and chemical interaction results in wearing out of the mud pump pony valves which becomes an expensive procedure for alto new ones. Datong Refractories knows basic price corresponding technology about extending the service life of refractory. All of our products were built to last, meaning you should not have to have them repaired or replaced often.

Each industrial furnace is a prototype with unique requirements and process conditions. We at Datong Refractories provide tailor-made solutions to suit varying requirements of varied industries. Whether you require a dedicated refractory for a specific temperature or chemical environment, our specialists can offer advice on selecting the right product to meet your needs. We collaborate with our customers, to listen and understand clients need to develop products that are made to perform at their best.

Selecting the best type of Refractory lining materials for your industrial furnace is a deciding factor for the useful service life of an industrial furnace. With the variety of choices on sale, it can be difficult to know what are the best materials to choose from. At Datong Refractories, we provide an expert consultancy service to help you with the maze of choosing your refractory lining material. We are a team of experts and are committed to helping you, giving full advice and assistance for you to make informed choices that best meets your needs.

The necessity of improved thermal insulation and energy conservation of refractory linings become pressing in the present rapidly developing industry. At Datong Refractories, we believe that investing in the best technology will ensure our products continue to outperform our competitors. Our TAB® thermal insulation systems not only improve the energy efficiency of industrial furnaces, but also result in cost savings and environmental benefits. We push the limits of refractory technology by using cutting-edge innovations in our products, allowing our customers to maximize their productivity and supercharge their efficiency.

We refractory lining high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

Datong invested 10 million yuan and built a chemical analysis lab, micro powder testing room, scanning electron microscope, application laboratory refractory lining as well as a pilot base. There are more than 40 sets various testing instruments including SEM energy thermometer XRD laser particle size analyzer, along with other world class testing and analysis equipment. The center employs more than 10 engineers and scientists, including a senior engineer, as well as two other engineers. The center also has a close cooperation with Wuhan University of Science and Technology and the Sinosteel Lioyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

refractory lining has achieved ls0900l quality system certification, is014001 environmental management system certification OHSAS1800 occupational and safety management system certification. is a national high-tech enterprise that was listed successfully on April7,2016 stock code: 836236. Today, it is the most complete and largest high-quality aluminum based refractory material base. Every tank is witnessed by a hydraulic test, an radiography test, etc. With the most advanced production equipment and strict quality control at every stage of production. We pay close attention to each detail and every little thing is an integral part of our company's workforce.

Kaifeng Datong refractory lining Co., Ltd. was established in 2008 and is a private joint stock company located in Henan province. It specialises in the manufacturing, development and sale of high-quality refractory material.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog