Refractolines nbsp;  of High nbsp;  Quality&  & on the Basis& of Industrial Furnaces

The selection of refractory lining material for a particular furnace depends on the temperature that it is required to withstand and the nature of the process carried out in it. Datong Refractories Having built and operated refractory plants for many years, we have in-depth knowledge of the conditions under which products are used on-site. Our refractory linings range is suitable for a broad array of industrial processes including excellent insulation as well as ability to withstand high temperatures and chemical attack. Partner closely with us and benefit from our Process Know-how, Experience through multiple projects implemented – we are the ideal partner for all sectors as industries look to make their furnace operations cost efficient.

One of the things that makes Datong Refractories so special to our customers is our focus on durability and lifespan in high-temperature environments. Made from special heat resistant materials, our furnace lining material can tolerate the high temperature in industrial furnaces with working life being long. Whether a steel or cement plant, for us, high-temperature processes have to be designed in such a way that the wear and tear on the materials is reduced as far as possible to keep downtime – which gets very expensive with many industrial kilns/furnaces – down. With Datong Refractories, you can rest assured about the integrity and dependability of your furnace lining even in the harshest operating environments.

At Datong Refractories, we are of the opinion that there is no need for quality to have expensive taste. That’s we we provide affordable options for heat management in production without sacrificing performance or reliability. Our lining materials feature exceptional heat insulation properties and high-temperature resistance to help industries enhance their energy savings, cut down on operating costs etc. By using Datong Refractories you could save a lot on your furnace operations with constant and efficient heat application for your production.

We know that every industrial furnace must be tailor-made with its own design and operating characteristics. And that’s where Datong Refractories provides bespoke solutions for every design and scale. Weather you have a batch type small furnace or a continuous production large equipment, we can collaborate with your own team in order to design an ad hoc refractory lining for Your needs. Our goal is simple From material selection through production, delivery and perfect fit installation, we believe no other company can provide you with a higher level of expertise in the field of custom shaped refractory.

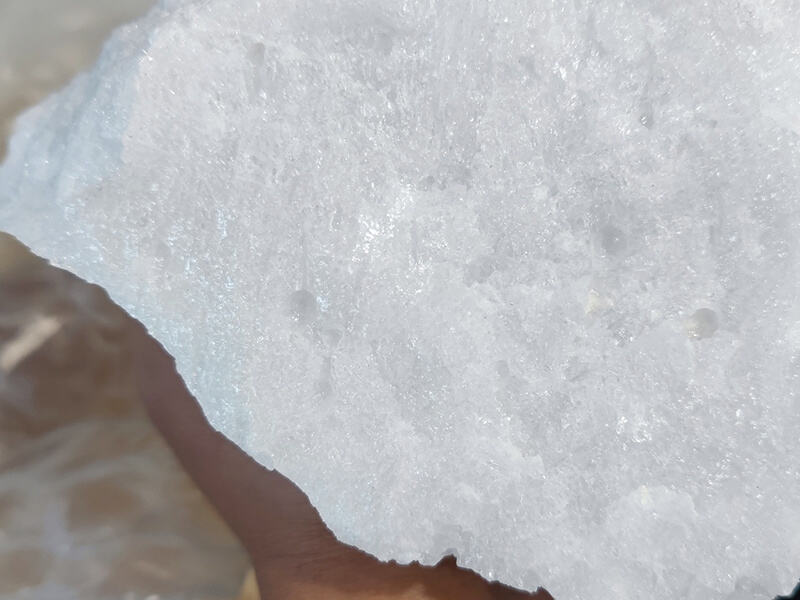

Selecting the proper refractory material for an industrial furnace will greatly help to ensure optimal relining with maximum service life. Datong Refractories offers professional advice in choosing which refractory is the best for you based on our experience and technical background. Whether you need a high thermal conductivity or great chemical resistance or superb mechanical strength, ... friends from Reactive α-AL₂O₃ Powder can help you to find the right solution for your application. You can rely on the strength and long-lasting product life of Datong Refractories.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a high-tech Refractory lining material private enterprise in Henan Province, that is specialized in the production, development and sales of high-quality Refractory raw materials as well as related products. After years of development that has never stopped the company now has an annual output of 30.000 tons of high temperature alumina powder 20.000 tons of magnesium aluminum spinel (electric melting melting and sintering) 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina tabular alumina, 8, 000 tons of non-crystalline calcium Aluminate, thirty-three tons of high aluminum cement, and 50, 000 tons of different products that can be castable and shaped.

Datong has invested Refractory lining material in the construction of the chemical analysis laboratory, micro powder testing room as well as a scanning electron microscope high-temperature laboratory for applications as well as a pilot base. There are over 40 sets of of testing equipment including SEM energy spectrumrometer XRD XRF laser size analyzer, along with other world class testing and analysis equipments. The center employs over 10 scientists and engineers comprising a senior engineer and two engineers. It also maintains a close cooperation with Wuhan University of Science and Technology and Sinosteel-Luoyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

Datong has achieved ls0900l certification for quality systems, as well as is014001 Refractory lining material, OHSAS1800 occupational health and safety management system certification. Datong is a national high-tech enterprise that was listed successfully on April 7th, 2016 with stock code 836236. It is now the largest and complete source of high-quality aluminum-based materials. Every tank is witnessed with hydraulic test, radiography test, air tight test, etc. The most advanced production machines around the globe ensure strict quality control throughout the entire production process. Every tiny detail deserves our attention and each little thing is an integral component of our team.

We Refractory lining material high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog