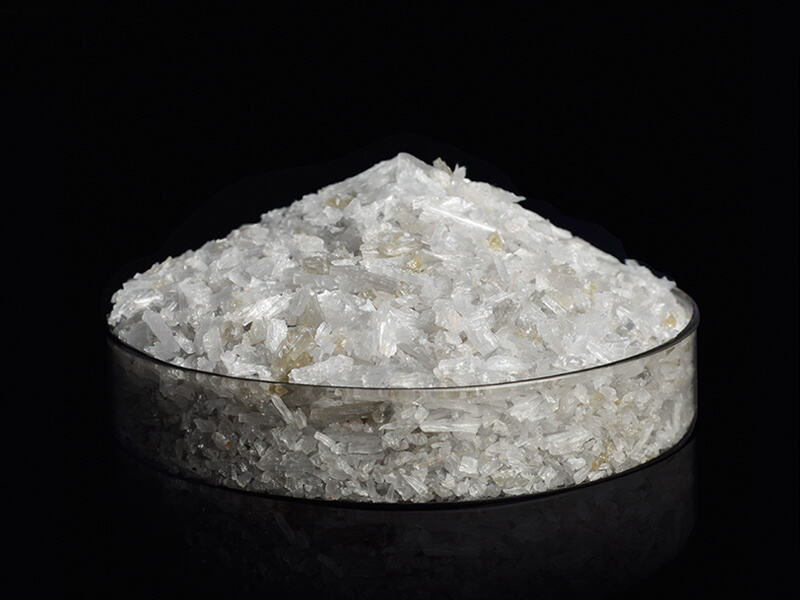

RAW SILICON CARBIDE: Datong Aluminic's raw silicon carbide is top of the line and known for its purity. Silicon carbide is a widely used abrasive owing to its high hardness, hard chemical inertness, high thermal conductivity, small wear, and good resistance to heat attack. Applications Our black silicon carbide is especially suitable for making grinding wheels, cutting wheels, fiber oil stone, wire saws, etc. We are in a position to supply superior quality product at competitive price as The natural/flake graphite powder provided by us can be applied in the manufacturing mold of diamond tools, high-purity metallurgy additives, and hard alloy which require the carbon addition rate over 98; PET carbon; Aluminum Carbon brick. Your products will be recognized for quality and their brilliance in performance and using our raw silicon carbide is one of the most effective means.

If you are trying to take your products to a higher level, the most reliable raw material solution is provided by our premium quality silicon carbide grits. We manufacture our silicon carbide with tight checks on particle size distribution and purity to provide optimal performance. From grinding wheels and cutting tools to surfacing optical lenses, our products are used in a variety of industrial and consumer product applications that require high quality, limpidity raw silicon carbide. You can boost the performance and durability of your products with our raw silicon carbide.

Here at Datong, we understand that businesses are in need of a cost-effective method to acquire silicon carbide material on the open market. That's why we do our best to provide you with the lowest wholesale prices on high quality raw silicon carbide. Whether you require a small order of raw silicon carbide or massive quantities, we can meet your budget to get you future-proof. Select Datong as the supplier, you can experience exquisite our raw silicon carbide and compete price of it waiting for your test.

For the production process to be smooth, especially when such raw materials as silicon carbide are concerned, it is very important to have a stable supply chain. Here at Datong, we have a strong and effective network with easy access to the most efficient logistics system for your raw silicon carbide requirements. With our efficient production system, you can also get orders filled in time to keep up with production schedules and customer demands. We are for reliability and efficiency, your reference partner to cover all your raw silicon carbide needs.

In today's competitive market, gaining an edge over your competition means having access to the best materials and design concepts that enhance product value. Datong raw silicon carbide products have an excellent resistance characteristic such as corrosion resistance, wear resistance, high temperature tolerance, and tear resistance. Select our raw silicon carbide if you're looking to incorporate a material that is stable, but still able to reach its optimal productivity. Trust Datong to provide you with the finest raw silicon carbide on the market and enable you to be wholesale competitive in your industry.

Datong invested 10 million yuan and built a chemical analysis lab, micro powder testing room, scanning electron microscope, application laboratory raw silicon carbide as well as a pilot base. There are more than 40 sets various testing instruments including SEM energy thermometer XRD laser particle size analyzer, along with other world class testing and analysis equipment. The center employs more than 10 engineers and scientists, including a senior engineer, as well as two other engineers. The center also has a close cooperation with Wuhan University of Science and Technology and the Sinosteel Lioyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

Kaifeng Datong Refractories Co., Ltd was created in the year raw silicon carbide and is a private joint-stock high-tech enterprise in Henan Province, specializing in the production, development and distribution of premium Refractory raw materials as well as related products. Following more than a decade of continuous growth the company now has an annual production of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting sintering), 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina and tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate 30, 000 tons of high aluminum cement and 50, 000 tons of various castings and shaped products.

Datong is a highly-tech national enterprise that has successfully passed the ls0900l certification to ensure quality system, the is014001 certification for environmental management systems, and the OHSAS1800 raw silicon carbide for occupational safety and health. It was listed on April 7 2016 under the stock code 836236. In recent times, it has evolved into the largest and most comprehensive quality aluminum-based refractory raw base. Every tank is subjected numerous tests, such as hydraulic testing and air tightness tests, radiography testing, etc. With the most advanced production equipment with strict quality control for every production step. We pay close attention to every detail, and every little thing is an integral part of our company's workforce.

We provide high-grade raw materials, a variety of valuable products, and raw silicon carbide, while growing together with our clients. While at the same time. Datong Company wants to create a win-win partnership with all its partners, enabling it to serve its customers better and supply them with top quality products.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog