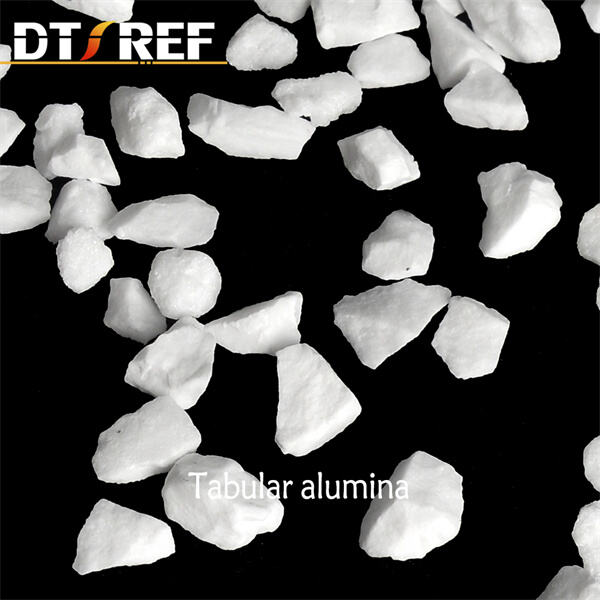

Tabular alumina is a kind of aluminum oxide used across different industries to support the productivity with its unique attributes. This unique stone is made from carefully selected bauxite or kaolin, which are then heated to very high heat temperatures in a special furnace.

Tabular alumina is conveniently baked aluminum oxide crystals renowned by their hardness and high fusion point, hence suitable for use in high-temperature environments. Furthermore, tabular alumina has excellent thermal shock resistance so that it can survive sudden changes in temperature without showing any damage by means of cracking or breaking.

New developments in the processing of tabular alumina

In recent years, packaging technologies for tabular alumina have also evolved substantially. These advancements have lead to the establishment of new technologies on how high-quality tabular alumina is manufactured, formulated and designed into different types of properties/shapes. This has led manufacturers to produce more cost-effective tabular alumina grades; the result of optimization in production processes which increased purity, consistency and upgraded particle size distribution.

Tabular Alumina - Applications Across Industries

Tabular alumina is widely used in the steel, ceramics, electronics and chemical industries. Its extreme high-temperature properties have made it an ideal refractory for use as a lining in furnaces, kilns and other thermal processes. Additionally, tabular alumina is also a key ingredient in making Abrasives, Catalysts and Polishing compounds.

Tabular alumina is distinguished from all other refractory materials by: A) its high degree of chemical purity, B) a mechanical strengthwhich is relatively unusual in oxide ceramics and C) crystalline size which can only be provided by sintered substances. One of the major reasons is that It has a very high melting point compared to other refractories thus could be suitable for operations in extremely high-temperature environments. In addition to the excellent wear resistance properties, tabular alumina exhibits an enhanced level of fracture toughness which decreases susceptibility to breakage under stress as compared with other refractories.

Experiments and industrial innovations by researchers, manufacturersIn order to reduce costs and improve performance in the manufacture of ceramic products several novel (alumina- tabular alumina) based materials are proposed. Compared to the use of only one kind of alumina, various composite materials with enhanced thermal properties as well as performances have been made by blending tabular and other refractory material together. Moreover, the option to form tabular alumina into different shapes like spheres, cylinders or plates has allowed us flexibility to be tailored as per requirements of end users. These advances have enabled the production of lower cost and higher performance tabular alumina-based materials.

Conclusively, tabular alumina exhibits comprehensive functionality and use scenarios in the industryropriating;arguments is a little bit tricky. These properties that make it very suitable for high temperature environments and its purity makes it a good option with sensitive applications where impurities might be issue. The future looks bright with tabular alumina and more to come, as proven by ongoing innovation in manufacturing techniques that enable an ever broad set of applications.

We Tabular alumina high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code Tabular alumina. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

Kaifeng Datong Refractories Co., Ltd. was founded in 2008, and is a private joint stock company located in Tabular alumina that specialises in the manufacturing as well as the development and sale of high-quality refractory material.

Datong has a budget of 10 million yuan. It has built Tabular alumina, micro powder testing laboratory as well as a room for scanning electron microscopy lab, application laboratory, high-temperature laboratory, and pilot base, with more than 40 sets of various instruments for testing, such as SEM Energy spectrometer, XRF, XRD particle size analyzer as well as many other world-class analysis and testing equipments. The technical center is home to more than 10 technical personnel which includes a senior engineer and two engineers, and maintains an ongoing relationship with Wuhan University of Science and Technology Sinosteel Luoyang Institute of refractories research University of Science and Technology Liaoning, Zhengzhou University and other researchinstitutes in the field of and refractory.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog