Alumina ball is a small, round object used in manufacturing processes and machinery associated with this lineTransforms alumina by heat into powderandas to surface area. Alumina has the highest hardness of any oxide and is very strong, making it resistant to heat treatments in certain applications. In consequence of these exceptional properties, the alumina balls are been used in numerous industries that aid to assist different functions. This article will help us in knowing how the alumina balls are formed and what purposes they serve to various fields, and why these plays a more significant role.

Bauxite is a mineral from which alumina derives. Common bauxites in the world can be found at different locations such as Australia, Guinea and Brazil. Bauxite is dug out of the ground in order to create alumina. They then transport the bauxite to a plant where it is cleaned. This is to get rid of any kind of impurities or extraneous material in the ore. In the end, we will get white powder of bauxite after cleaned. These powders are made into alumina balls - spheres that can be molded and used for all sorts of applications.

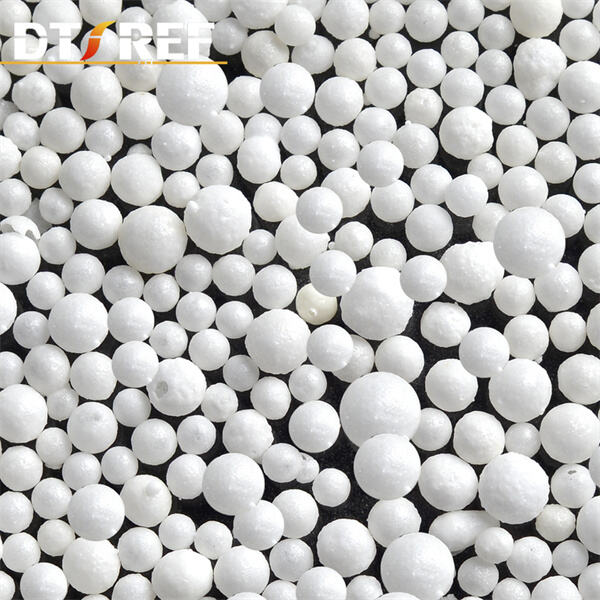

These balls are available in various sizes and shapes of alumina. They may range in size, from the tiniest grains of sand (tiny) to as large and visible a golfball with disk. The Shape and Size of The Alumina Ball: It depends completely on the need for which industry has been using these balls into its tasks. For instance, in mining industry they are used to refine and crush rocks and ores into a fine powder. This is relevant as the higher a material gets, the less difficult it becomes for process smaller. The alumina balls are very important in grinding materials when it comes to manufacturing all kinds of products. To produce great results in these processes the size and shape of alumina ball should be just right.

At such high temperatures, alumina balls are very beneficial. This makes them very useful in steel or ceramics industries where high temperatures are standard. For instance, it can be used to retain heat in furnaces and kilns with different shapes of alumina balls. In this way, they will save energy the make it more efficient. On top of that, alumina balls can also be a catalyst for accelerating chemical reactions in high-temperature situations which is why it becomes widely used during various industrial processes.

This one is a solid work horse in the industry that provides quick solutions of catalytic responses - this describes exactly how it plays an important role inside the catalyst running market. Catalysts are unique substances which raise the speed of a chemical reaction without experiencing an enduring physical or substance change. That way, they can use reactions over and over again. The balls can be coated with a variety of metals and chemicals to act as a catalyst for specific chemical reactions. The unique catalysts have a variety of uses, including for product creation and environmental cleanup efforts. Alumina balls have a higher reactivity with other compounds, and this is why they are considered an essential part of most manufacturing processes.

Alumina balls are hated tough along with wear-resistant features. This means they are durable and can endure a lot of use without falling apart. Typically used in high wear and tear workplaces, as example those of the mining industry or construction. One example is to use alumina balls inside the piping and equipment. This lining is intended to help reduce friction, which deteriorates the equipment over time reducing its life. On the other hand, they can be also used as wear-resistant coatings of all surfaces against damage and may considerably extend life cycle of these approached materials.

Datong invested 10 million yuan and built a chemical analysis lab, micro powder testing room, scanning electron microscope, application laboratory Alumina ball as well as a pilot base. There are more than 40 sets various testing instruments including SEM energy thermometer XRD laser particle size analyzer, along with other world class testing and analysis equipment. The center employs more than 10 engineers and scientists, including a senior engineer, as well as two other engineers. The center also has a close cooperation with Wuhan University of Science and Technology and the Sinosteel Lioyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

We provide high-grade raw materials, high-quality products, and services, as we grow with our customers. While at the same time. to better serve customers offer customers other similar products of a high standard, Datong Company is willing to create and Alumina ball relationships with all its partners!

Kaifeng Datong Refractories Co., Ltd was created in the year Alumina ball and is a private joint-stock high-tech enterprise in Henan Province, specializing in the production, development and distribution of premium Refractory raw materials as well as related products. Following more than a decade of continuous growth the company now has an annual production of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting sintering), 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina and tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate 30, 000 tons of high aluminum cement and 50, 000 tons of various castings and shaped products.

Datong has achieved ls0900l certification for quality systems, as well as is014001 environment management system certification OHSAS1800 Alumina ball, is a high-tech national enterprise which was able to be listed on April 7, 2016 stock code: 836236. Datong has become the largest and most comprehensive resource of high-quality aluminum-based materials. Every tank is inspected by a hydraulic test, an radiography test, and air tight test, etc. With the most advanced production equipment, strict quality control on each production stage. We pay attention to every single detail, and every single action is an integral part of our team.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog