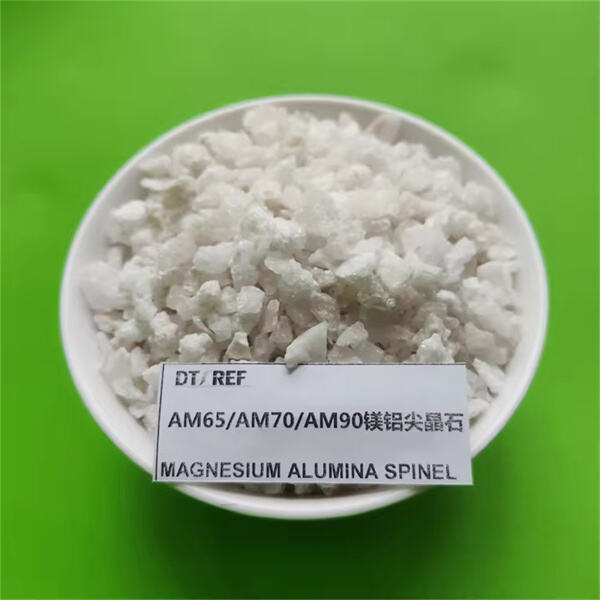

Fused magnesia-alumina spinel is indeed an excellent high-temperature frowned upon material formed by fushing MnO and Al2O3 in arc furnace. Despite its tongue-twister name, this material is actually pretty interesting and has so many incredible applications that allow it to shine in the realm of engineered manufacturing.

The application of fused magnesia alumina spinel in refractory materials is one its key advantages. These materials are created in a way to resist the high temperatures and shield other substances from heat. All is necessary to preserve the workability of material in environments such as furnaces and ovens where temperatures reach above a blistering 1,500 degrees Celsius.

Adding fused magnesia alumina spinel to refractories significantly improves their thermal shock, spalling and creep resistance. Put simply these are materials that even on prolonged exposure to high temperatures can continue functioning safely while still holding their shape! Ultimately, fused magnesia alumina spinel strengthens other refractory materials and enhances their wear resistance properties.

The properties of fused magnesia alumina spinel, for example. This ceramic is not only chemically stable, and therefore virtually universal corrosion resistant but also one of the high temperature materials that have a thermal expansion comparable to steel.

Because of these excellent performances, in addition to its use as a monolithic refractory material) also Fused Magnesia Alumina Spinel is widely used. It is used in the manufacture of ceramics and abrasives, as well as in environmentally significant processes like water purification where it has an important role helping to remove heavy metals and pollutants from waters.

Fused magnesia alumina spinel is extensively used in manufacturing and construction where it allows many uses due to its resistance to heat. The material are often made use of when developing top-notch oven furnishings, which is the components inside an stove that sustain things being heated. Moreover, fused magnesia alumina spinel can be used as a reliable coating to protect metals from high temperature and corrosion.

In construction /FMS, as a coating for wear-resistant surfaces such as floors and walls. It can also be combined with cement to produce concrete mixtures that are highly resistant to chemical erosion, which is a common problem encountered in wastewater treatment facilities.

Understanding the Chemistry and Crystal Structure of Spinels Based on Fused Magnesia Alumina

Fused magnesia alumina spinel, which is a single-phase solid solution with only one composition phase and exists in the structure form of magnesium aluminum oxide, but it contains extremely powerful properties technology. It is 80% magnesia (MgO) and 20% alumina (Al2O3), that are fused at high temperatures. All of these components add different characteristics to the mix.

It has a similar interesting structure of fused magnesia alumina spinel. The crystalline structure derived from the arrangement of these magnesia atoms and alumina comprises a powerful material with high mechanical strength, durability, along with extraordinary resistance to both thermal as well chemical impacts.

The use of fused magnesia alumina spinel in the refractory field has caused a revolution on many fronts. Because of its extraordinary characteristics, one can make materials from it which are stable at higher temperatures and have long service lives so that one then gets more efficient production processes at lower costs.

Chronic disease is preventingExcludingNew environmental application of this fused Magnesium aluminate spur multititerAnd it openMoreForeground. This best-in-class resistance to corrosion and chemicals has placed FRP high on the list for wastewater treatment plants. Furthermore, it has been used in building materials for safer and sturdier buildings.

To summarize, a little of the revelation for fused magnesia alumina spinel and we can determine that this is an amazing material which has numerous excellent properties to be used in many industries. It is highly resistant to both thermal and chemical degradation due to its unique crystal structure that enhances the loading characteristics of ITO/YSZN. Ranging from refractory to ceramics, abrasives and environmental services the fused magnesia alumina spinel provides unsurprisingly high-strength compositions that possess high resistance in even most extreme operational conditions.

We provide high-grade raw materials, a variety of Fused magnesia alumina spinel, and services, while growing together with our customers. While at the same time. Datong Company wants to create an all-win-win partnership with its partners in order for it to be able to serve customers better and offer them quality products.

Datong has a budget of 10 million yuan and has built a chemical analysis laboratory and a micro-powder testing laboratory with a scanning electron microscope Application laboratory, high temperature laboratory and pilot base, including more than 40 sets of testing equipment, including SEM and Fused magnesia alumina spinel, XRD, XRF, laser particle size analyzer, as well as other top-of-the-line analysis and testing equipments. The technical center employs more than 10 technical personnel with 1 senior engineer and two engineers. The center maintains the close collaboration with Wuhan University of Science and Technology Sinosteel Luoyang Insimuie of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of refractory.

Datong has been awarded Fused magnesia alumina spinel quality system certification, is014001 environmental management system certification OHSAS1800 occupational and safety management system certification, is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code 836236. Nowadays, it has become the largest and most complete quality aluminum-based refractory raw material base. Each tank is scrutinized by means of a hydraulic test and radiography test, and air tight test, etc. The most advanced production machines in the world guarantee strict quality control at every stage of production. We pay close attention to every detail, and every little thing is a part of our workforce.

Kaifeng Datong Refractories Co., Ltd was created in the year Fused magnesia alumina spinel and is a private joint-stock high-tech enterprise in Henan Province, specializing in the production, development and distribution of premium Refractory raw materials as well as related products. Following more than a decade of continuous growth the company now has an annual production of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting sintering), 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina and tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate 30, 000 tons of high aluminum cement and 50, 000 tons of various castings and shaped products.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog