The quality of refractory material is important for getting the best performance from glass furnaces. Datong knows the significance of superior glass furnace refractory in increasing efficiency and productivity. By choosing high-quality materials, businesses can help limit downtime and maintenance costs while increasing overall operational output. So let’s take a closer look at how choosing the correct glass furnace refractory can significantly benefit your manufacturing operations.

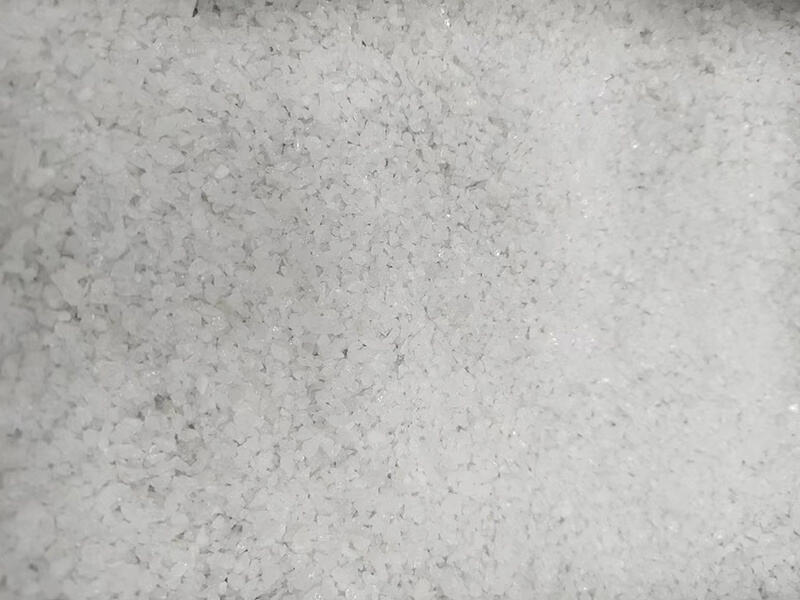

Datong provides a variety of top-quality glass furnace refractory Bubble Alumina wholesale. From the right bricks to castables, our products are built for high heat and rugged applications, long-lasting strength. Through volume buying, manufacturers can reduce costs and have a steady supply of refractories for their glass tanks. Datong wholesale provides businesses an alternative to purchasing cheaply made, lower quality products that may not perform as expected. Thanks to our robust products, organizations will be able to optimize production processes and improve overall glass production with these benefits.

There are a set of essential considerations for selecting the appropriate glass furnace refractory. One important factor to consider is what kind of glass to melt in the furnace. Various refractory materials are used depending on the melting temperature of the glass being melted.

Another variable to consider is the temperature from which your furnace will be running. There are refractory materials that work well at higher temperatures, as well as some better for lower! The refractory material should be able to accommodate the temperature range of your glass furnace.

You will also want to contemplate the shape and size of your furnace, and any special design features it might have. Certain refractory materials are best suited for certain furnace shapes, or designs, so be sure to choose an appropriate material for the structure you’re using.

When it comes to common refractory problems in glass furnaces and how to try and tackle them, one potential issue which may occur is cracking or spalling of the refractory. This may occur because of thermal shock, mechanical stress, or chemical reactions occurring inside the furnace. To avoid this situation, it is necessary to use a quality refractory material with a resistance suitable for these factors.

With rubble formulations advancing in terms of the latest technologies used for glass furnace refractories, a lot has changed over the past few years. A far more exciting development comes with the use of advanced ceramics, which provide improved durability, thermal stability, and chemical resistance. These newly-developed materials are contributing to extending the life of the glass furnace refractory, which leads to more efficient operation of furnaces in general.

glass furnace refractory has achieved ls0900l quality system certification, is014001 environmental management system certification OHSAS1800 occupational and safety management system certification. is a national high-tech enterprise that was listed successfully on April7,2016 stock code: 836236. Today, it is the most complete and largest high-quality aluminum based refractory material base. Every tank is witnessed by a hydraulic test, an radiography test, etc. With the most advanced production equipment and strict quality control at every stage of production. We pay close attention to each detail and every little thing is an integral part of our company's workforce.

glass furnace refractory has invested approximately 10 million yuan, and has constructed a chemical analysis laboratory, micro powder testing laboratory, scanning electron microscope room lab, application laboratory, high temperature laboratory and a pilot base with more than 40 different testing instruments, including SEM, energy spectrometer, Laser particle size analyzer as well as many other world-class analysis and testing equipments. The center employs more than 10 scientists and engineers including a senior engineer and two other engineers. It also maintains close partnership with Wuhan University of Science and Technology and sinosteel Luoyang Institute of Refractories Research, University of Science and Technology Liaoning and Zhengzhou University.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a private joint-stock high-tech enterprise located in Henan Province that specializes in the creation, production and sales of high-quality refractory raw materials and Related products. Following years of development that has never stopped, it now has an annual production of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting and melting and sintering) 10, 000 tons of calcium aluminate, glass furnace refractory white fused alumina tabular alumina. There are 8, 000 tons of calcium aluminate that is not crystallized, 30, 000 tons of high aluminum cement and 50, 000 tons of different castable and shaped products.

We provide high-grade raw materials, a variety of valuable products, and glass furnace refractory, while growing together with our clients. While at the same time. Datong Company wants to create a win-win partnership with all its partners, enabling it to serve its customers better and supply them with top quality products.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog