The Versatile Nature of Bubble Alumina used in Different Industries

The raw material is called Bubble Alumina and it is used in many different fields. This special material is die-cast from aluminum oxide, and it has attracted industrial applications with lots of benefits. Materials that offer great insulation, durability and lightness even at increased temperatures to provide cost-savings tend to confirm of enormous assets for an easy guide this kind. Bubble Alumina's use in various businesses proves its price style within the term redoubled potency during a pocket-friendly.

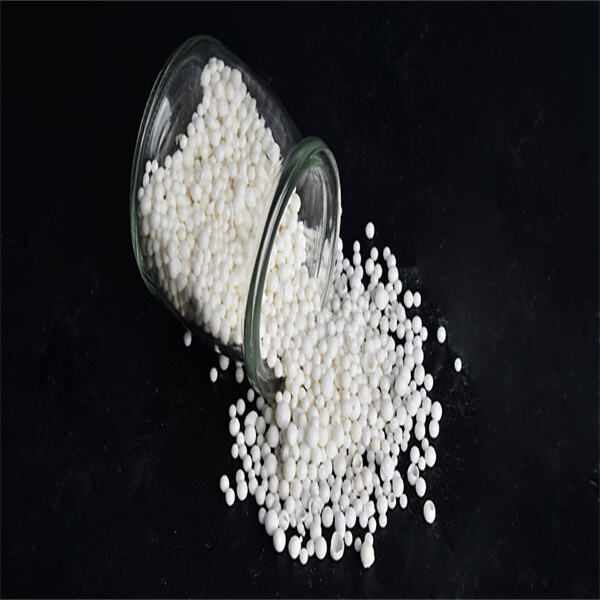

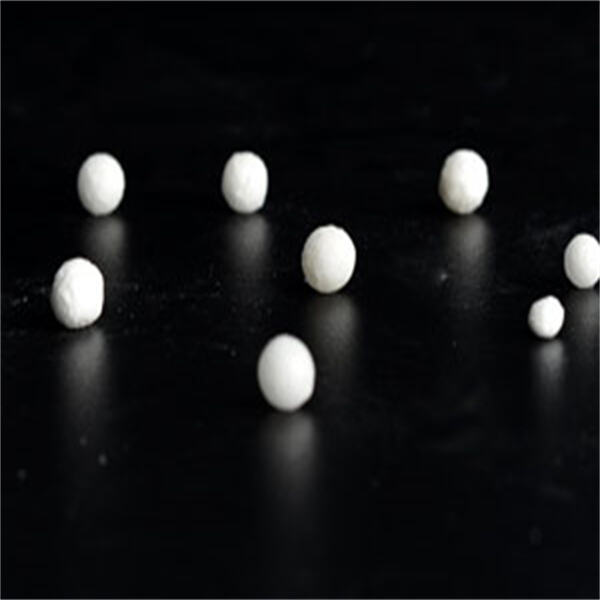

Bubble Alumina is one of the key materials used for insulation, coating and preparing refractory material which makes it an essential raw material in multiple end-user industries such as ceramics. Bubble Alumina is primarily responsible for minimizing heat loss and in turn, energy usage by helping to protect equipment used within the higher temperature environments like those found in industrial processes. This incredibly versatile material available in a range of forms including blocks, grains and powders as well as coatings can easily be incorporated into different types of processes and products to meet particular needs.

Bubble Alumina is an insulating refractory product which provides excellent insulation properties. Efficient Heating in Furnaces Bubble Alumina helps maintains the heat loss at minimum, which maximises energy rate resulting to low cost of repairs and reduced power bills. In addition, heating pipes in good operating conditions with this material will prevent conduction energy dissipation. Apart from industrial usage, Bubble Alumina insulation materials are also used in homes and commercial buildings to provide better thermal-insulation for walls and ceilings which help reduce ever-rising energy bills.

Bubble Alumina is different than any of the traditional refractory materials as it does not contain harmful substances such as silica, which makes it a non-toxic environmentally friendly solution. It is not possible for Bubble Alumina to give off any toxic emissions in the environment as it is free from chemicals and natural goods are used, so industries wanting a sustainable method of production can cleanly move forward with advanced surfacing.

The usage of Bubble Alumina has been increasing drastically in all high-temperature applications because they are very light, last the longest and highly insulative. Bubble Alumina possesses remarkable resistance to high temperatures, making it invaluable in its use within industries such as cement manufacture, ceramics and metalworking. Additionally, the uses of Bubble Alumina span conventional industrial processes and high-temperature aerospace/defense environments alike. As Bubble Alumina further improves as due to technological innovations, this material could change the rules of any industry which requires high-temperature materials.

Bubble Alumina is thus a useful resource indeed, which provides many applications for insulation / refractory materials and high temperature situations. Its not only helpful in cutting energy costs but also doing some part of saving environment. With these advanced Bubble Alumina materials developed by manufacturers, it is easy to see their widespread adoption across a multitude of industries as they continue reinventing ways in which efficiency and sustainability could be taken hand-in-hand.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a high-tech Bubble Alumina private enterprise in Henan Province, that is specialized in the production, development and sales of high-quality Refractory raw materials as well as related products. After years of development that has never stopped the company now has an annual output of 30.000 tons of high temperature alumina powder 20.000 tons of magnesium aluminum spinel (electric melting melting and sintering) 10, 000 tons of calcium aluminate cement, 50, 000 tons of white fused alumina tabular alumina, 8, 000 tons of non-crystalline calcium Aluminate, thirty-three tons of high aluminum cement, and 50, 000 tons of different products that can be castable and shaped.

We offer top-quality raw materials, high-quality products, and services, and we are growing with our customers. While at the same time. in order to provide Bubble Alumina to customers, provide customers with other related quality products, Datong Company is willing to create and win-win cooperation with all its partners!

Datong has achieved ls0900l certification for quality systems, as well as is014001 environment management system certification OHSAS1800 Bubble Alumina, is a high-tech national enterprise which was able to be listed on April 7, 2016 stock code: 836236. Datong has become the largest and most comprehensive resource of high-quality aluminum-based materials. Every tank is inspected by a hydraulic test, an radiography test, and air tight test, etc. With the most advanced production equipment, strict quality control on each production stage. We pay attention to every single detail, and every single action is an integral part of our team.

Datong invested 10 million yuan and built a chemical analysis laboratory which includes a Bubble Alumina with a scanning electron microscope application laboratory high temperature laboratory, pilot base and more than 40 sets various tests instruments, such as SEM energy spectrumrometer XRD XRF laser size analyzer and various other world-class test and analysis equipments. The technical center employs more than 10 technical personnel comprising 1 senior engineer and 2 engineers. Datong maintains a close cooperation with Wuhan University of Science and Technology Sinosteel Luoyang Institute of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of the field of refractory.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog