In a large number of industries, alumina grinding is indispensable such as in car and airplane industries. And hence the materials produced are special which can then be used in increasing and upgrading the other machine materials. Datong, one of the alumina grinding companies. They use only the most advanced and up-to-date technology to ensure that they provide top-grade materials.

Alumina is a pale fiery debris weighty, lightweight and extremely goozy raw material which is utilized in the production of grinding media. One of the steps in this process is to break the raw alumina into pieces. Special machines are used for this; their primary aim being that they render the alumina into crushed grains without cracking it. This is critical as damage to the alumina would ultimately result in less quality product.

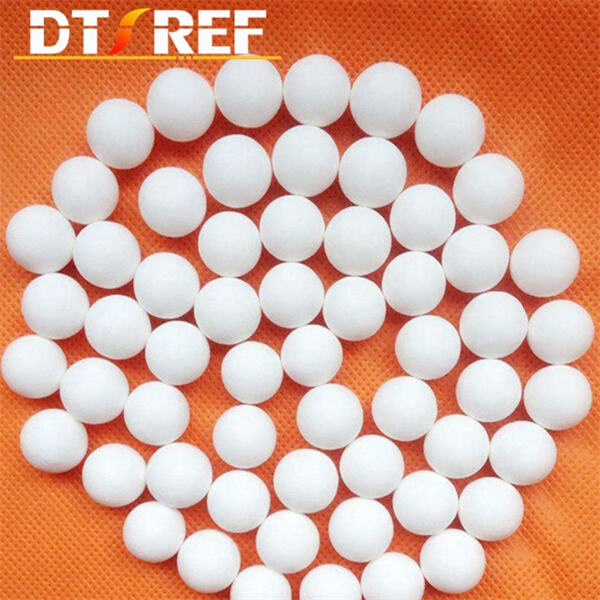

This is when the alumina breaks down into smaller pieces, and it mixes with other materials to create a thick slurry. This thickened Datong alumina grinding ball is then made into molds. It is then oven dried in the molds. This is a critical point as the drying process allow removes any water that might be left in the mixture. Still, that is only one molecule of water too many for the final product and would ruin it.

Once the slurry has dried, take out of mold and then it’s all set to go to the following process. The media is subsequently placed in a furnace and the temperature is raised to an extremely high level. The sintering process involves heating. Now we end up with a very strong, super tough material that can take an absolute kicking as the heat from sintering melds alumina particles together.

A crucial to the good alumina grinding methods is a reliable technique for propagating machine wear. A bed of particles. Means they lean during autogenous and semi autogenous efficient grinding media. The diagnostic tests are invaluable because they enable turning any mill designed for the production of specific natural materials into an outstanding mass media, and not as at stage (k) a variety of complex factors cross-European ought to have been taken into account when choosing specifically mill should purchase or read. Ball Andersen et al Mills Supported Wet Milling O2Open utilizing Blast furnace slag undertook single-stage milling experiments in their own laboratory burner. CanCem started running course circulations in 2007 main inside the chemicals division afterwards inside clinker-grinding section onward as well as extra grinding vertically inside a Loesche (Fig. Mill best behavior ability( t/min) comparative to revolution speed -consumption rates plus insulation at identical chamber

There are a few important factors for the selection of the correct grinding media for any given application and some of these are described below. The hardness of the Datong alumina grinding balls that it grinding is the most important. The adjustment of the grinding media hardness is also very required, because different materials use their own appropriate grinding media. The result is an inefficient process because of poor grinding performance through the incorrect media selection.

Most Common Materials used: Zirconium Oxide, Silicon Nitride, Aluminum Oxide Ceramics are Material which are Used Frequently in Many Ceramic Machining Applications. These materials possess their own properties that separate one from another (eg. hardness, thermal conductivity). The three properties heavily influence the Datong alumina grinding balls, so it is necessary to confirm that proper selection happens.

We provide high-grade raw materials, high-quality products, and services, as we grow with our customers. While at the same time. to better serve customers offer customers other similar products of a high standard, Datong Company is willing to create and Alumina grinding relationships with all its partners!

Kaifeng Alumina grinding Refractories Co., Ltd. was founded in 2008 and is a private joint stock company in Henan province. The company specializes in the production and development of high-quality refractory material.

Datong is a highly-tech national enterprise that has successfully passed the ls0900l certification to ensure quality system, the is014001 certification for environmental management systems, and the OHSAS1800 Alumina grinding for occupational safety and health. It was listed on April 7 2016 under the stock code 836236. In recent times, it has evolved into the largest and most comprehensive quality aluminum-based refractory raw base. Every tank is subjected numerous tests, such as hydraulic testing and air tightness tests, radiography testing, etc. With the most advanced production equipment with strict quality control for every production step. We pay close attention to every detail, and every little thing is an integral part of our company's workforce.

Datong invested 10 million dollars and constructed a chemical analysis lab and a micro-powder testing room, Alumina grinding, application laboratory high temperature laboratory pilot base, and over 40 sets of various testing equipments, including SEM energy thermometer XRD laser particle size analyzer, and other top testing and analysis equipment. The technical center employs over 10 technical employees with 1 senior engineer and 2 engineers. It maintains a closely working relationships with Wuhan University of Science and Technology Sinosteel Luoyang Institute of research in refractories, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of Refractory.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog