Alumina refractory is a different type of material which very dense and strong, due to this fact it can serve withstand the high temperature without decomposing or disintegrating. Such a device is produced from alumina, which is basically a ceramic material. Ceramics are notoriously hard and typically were intended for heavy-duty applications. The alumina refractory is a high temperature content that enjoys some of the most critical features making it ideal for certain situations where you have temperatures touching on heights.

Out of all the characteristics possessed by alumina refractory, one of its key features is that it remains stable under immense heat. These Oxides are so strong that they can become brittle even at temperatures of 2000 degrees Celsius! It has this amazing property which involves high heat absorption, - hence it is ideal for use in appliances like the average furnace or kiln. Melting metals and other similar materials require such high temperatures, so a material has to be able to resist as well.

In addition, alumina refractory material is also resistant to the damage of harsh chemicals or very rough materials. Which means it will stand up to tough things like in mining and chemical processing as those can use strong (and sometimes dangerous) materials. The equipment used in these industries is often subjected to very harsh conditions, and the use of alumina refractory helps protect such equipment ensuring it stays safe and operational.

Alumina Refractory has some big perks, not the least of which is its capacity to resist high temperatures without melting or letting heat through. This is what makes it suitable for application in places that other materials would erode too fast. This is what makes the alumina refractory so ideal for operations like mining, chemical processing and steel production where effective materials are a must!

Alumina refractory for the steel sector,where it protects the walls of a furnace as metals are being melted. This is done to avoid wearing out the wall and thus making your furnace more durable, while needing much less regular maintenance. A better protected furnace is one that allows production to be performed smoothly, without the need for a break every now and then so it can go through repairs.

There are some steps to prolong the lifespan of alumina refractory in furnaces. 1- Setting Up The Right Way First and foremost, it needs to be installed the right way. That is, choosing the appropriate size of refractory lining for each caseInstalling it by typical ways securing all required sections properly. Installation must be correct or the material will not perform for long periods.

Keeping alumina-made refractory well-maintained is another way to make the material last longer. This consists of the regular checking for indications or wear and damage. Regular inspections could also be of help in noticing the prospective issues before it develops into a severe problem. Further, refurbishing of refractory such as cleaning and repairing the damaged world can help to use it for an extended period.

Datong is a highly-tech national enterprise that has successfully passed the ls0900l certification to ensure quality system, the is014001 certification for environmental management systems, and the OHSAS1800 alumina refractory for occupational safety and health. It was listed on April 7 2016 under the stock code 836236. In recent times, it has evolved into the largest and most comprehensive quality aluminum-based refractory raw base. Every tank is subjected numerous tests, such as hydraulic testing and air tightness tests, radiography testing, etc. With the most advanced production equipment with strict quality control for every production step. We pay close attention to every detail, and every little thing is an integral part of our company's workforce.

We offer top-quality raw materials, high-quality products, and services, and we are growing with our customers. While at the same time. in order to provide alumina refractory to customers, provide customers with other related quality products, Datong Company is willing to create and win-win cooperation with all its partners!

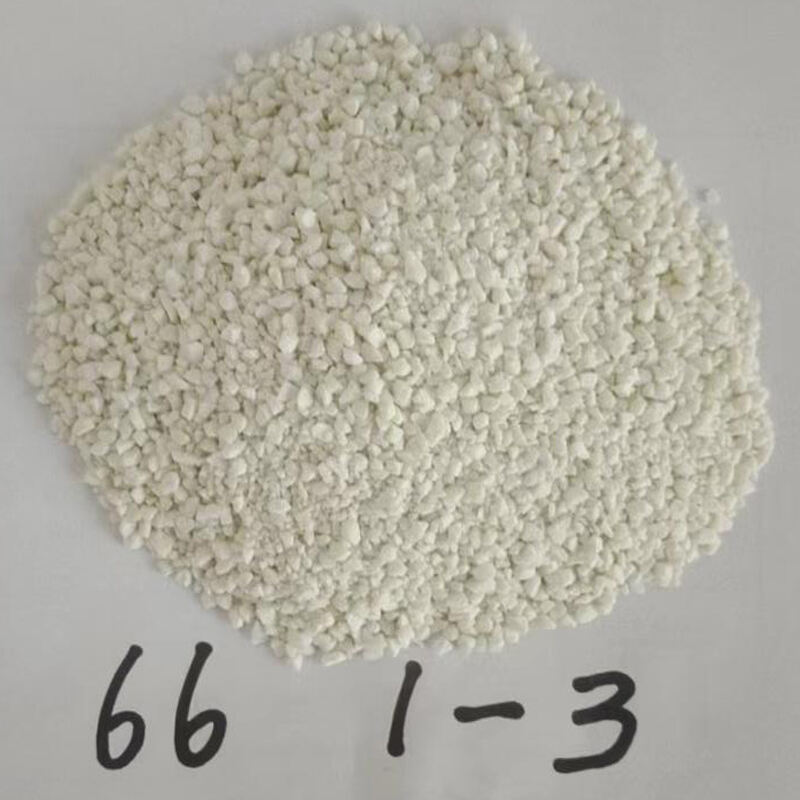

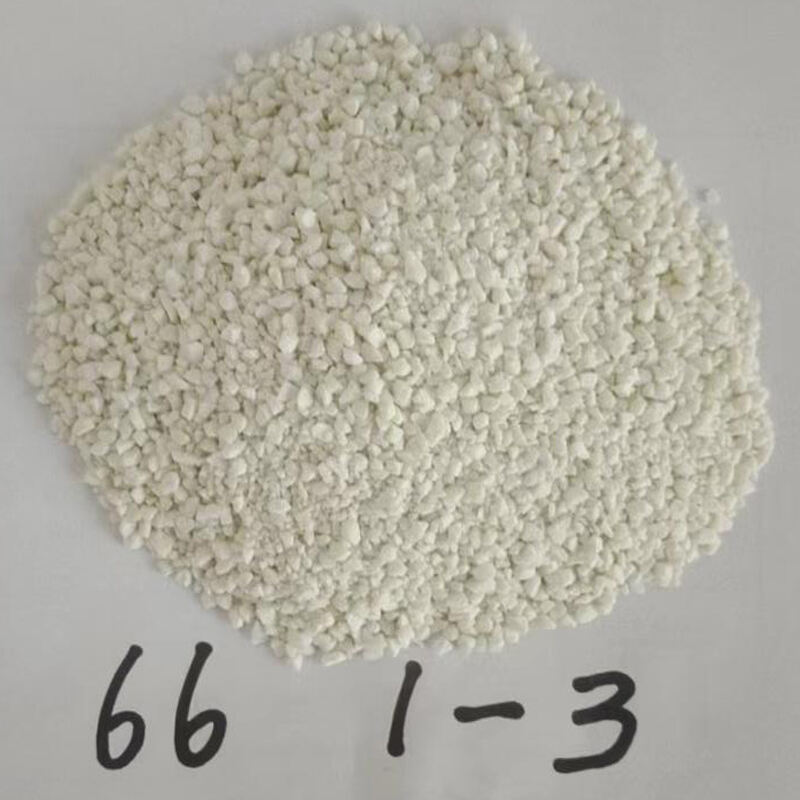

alumina refractory Datong Refractories Co., Ltd was established in 2008. It is a high-tech joint-stock private enterprise in Henan Province, which specializes in the development, production and distribution of premium refractive raw materials and related products. After years of continuous development the company now has an annual output of 30.000 tons of high-temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting the sintering) 10, 000 tons of calcium aluminate, 50, 000 tons white fused alumina, tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate, 30000 tons of high-alcohol cement, and 50, 000 tonnes of various castings and shaped products.

Datong invested 10 million yuan to construct the chemical analysis laboratory with a micro powder testing room as well as a scanning electron microscope high-temperature laboratory for applications, pilot base and over 40 sets of of testing equipment including SEM energy instrument XRD XRF spectrometer laser particle size analyzer, as well as other top analytical and testing equipments. The center employs over alumina refractory and engineers, including a senior engineer and two other engineers. It also maintains close partnership with Wuhan University of Science and Technology and sinosteel Luoyang Institute of Refractories Research, University of Science and Technology Liaoning and Zhengzhou University.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog