Ladle refractory lining is a major concern for the steel industry that is used to protect ladles from high temperatures and molten metal corrosion. Material lining can resist high temperature and harsh condition, thus achieve the purpose of ladle without contaminating or being eroded. Ladle lining products Datong's line of ladle linings is tailored made to meet the metallurgical requirements of steel makers, providing a solid protecting action and peak performance.

Ladle lining is very important in the steel industry with multiple benefits. In the first place when you use a properly lined ladle, it will help to keep your molten steel good because there is no undesirable reactions and/or impurities in the metal. This provision will help to make the final product meet the desired strength and durability specifications. In addition, ladle lining can prolong the life of the ladle - reducing the amount of times that a manufacturer will need to repair or replace a ladle, and ultimately saving on costs. Through purchasing of Datong's high-grade ladle lining products, steel corporations will be able to achieve better efficiency and productivity, as well as overall performance.

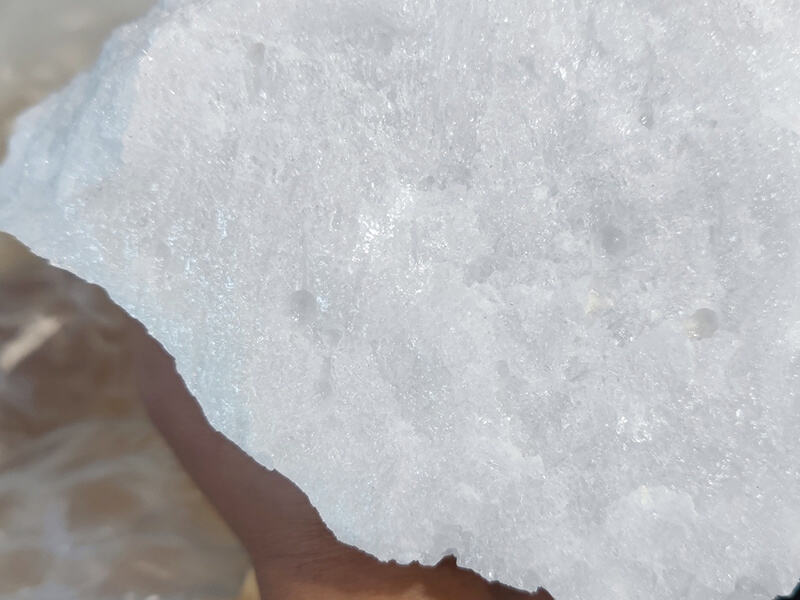

Ladle Linings Datong provides a complete range of lined ladles for steel makers. Whether a producer needs ladle lining material in Al2O3 or Mg0 forms, Datong both the bulk and custom solutions that are able to provide affordable cost-effective products. When steel companies collaborate with Datong for wholesale ladle lining products, they gain access to top-quality products, technical expertise and responsive service, allowing them to keep their processes on the right track. Ladle Lining Solutions Steel makers can rely on Datong for excellent pre-cast and lined ladle solutions to improve performance, minimize downtime and streamline production for optimal yield. Reactive α-AL₂O₃ Powder

Ladle lining is an essential factor in the production of steel to guarantee the quality of molten metal. Correct application of ladle lining is a key factor in preventing loss of heat and keeping the temperature at the required level, as well as to protect the ladle from corrosion. To apply ladle lining properly, start by cleaning the ladle surface effectively eliminating any debris or old lining. Now the lining material must be cut to shape so that it is able to fit around the ladle. Then put a coat of adhesive on the ladle surface and put the lining. Wait, no – I mean the lining of the ladle is steel!! Well obviously it's easy to forget things like that. :) But be sure push down firmly on the lining to really make a tight seal between it and the ladle. Finally, leave the glue to dry and you are ready to use your ladle for steel. In this way, ladle lining will be installed correctly and effectively play a role in the steel-making procedure. Calcined α-AL₂O₃ Powder

For steel plants that need ladle lining material in large quantity, Datong can be counted as a trusted source of high-grade quality with competitive price. Datong can provide comprehensive types of ladle lining materials, such as refractory bricks (not only magnesia-chrome bricks, but also magnesia-spinel and alumina-magesite bricks), castables and mortars for different ladles with different sizes and working conditions. Steel makers will save themselves from packing logistics and receive the timeous supply of material. Furthermore, Datong offers technical assistance and guidance to help its customers find the best ladle lining products for their particular steel making requirements. Trusted by Datong, and steelmakers can achieve consistent mineral quality delivery performance benefits of the switch leakage fill material in their production process requirements! Fused alumina magnesia spinel

Datong has invested ladle lining in the construction of the chemical analysis laboratory, micro powder testing room as well as a scanning electron microscope high-temperature laboratory for applications as well as a pilot base. There are over 40 sets of of testing equipment including SEM energy spectrumrometer XRD XRF laser size analyzer, along with other world class testing and analysis equipments. The center employs over 10 scientists and engineers comprising a senior engineer and two engineers. It also maintains a close cooperation with Wuhan University of Science and Technology and Sinosteel-Luoyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code ladle lining. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

Kaifeng Datong Refractories Co., Ltd was created in the year 2008 and is a private joint-stock high-tech enterprise located in Henan Province that specializes in the creation, production and sales of high-quality refractory raw materials and Related products. Following years of development that has never stopped, it now has an annual production of 30.000 tons of high temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting and melting and sintering) 10, 000 tons of calcium aluminate, ladle lining white fused alumina tabular alumina. There are 8, 000 tons of calcium aluminate that is not crystallized, 30, 000 tons of high aluminum cement and 50, 000 tons of different castable and shaped products.

We provide high-grade raw materials, a variety of valuable products, and ladle lining, while growing together with our clients. While at the same time. Datong Company wants to create a win-win partnership with all its partners, enabling it to serve its customers better and supply them with top quality products.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog