Refractory bricks of Datong are unique type of brick which can bear very high temperatures and that too, without getting deformed. Not only are these fire bricks able to withstand higher temperatures, but they can also endure more pressure and last longer than average building block. Constructed from alumina, likewise silica (SiO2), magnesia as well zircon in particular material formulation. The refractory binder are made from these substances as they have very special characteristics. Therefore they can remain harder as well last longer also on the hardest of atmospheres.

So now you will help the best materials to make your Datong refractory bricks. Proper brick selection is important and along with the right choice of materials makes a building able to withstand different conditions and make it last longer. Make sure that you chose good quality durable materials for your project This history serves the best raw material in these and good suppliers for a purpose should be well versed with it. The refractory cement have to produce materials that meets the market requirements.

This is due to the fact that highly graded materials are used in making them. Not surprisingly, the bricks probably did have a short life and worked poorly because there was an inadequate portion of materials. Uniform quality is verified by tests and inspections. Another few requirements which some good mills have is to check on raw materials, ensuring the standards compliance and performance for usages. Manufacturers can now detect the issues with materials using these tests and even do necessary things to correct it.

You are now supposed to think over the number of best ways based on which all those Datong materials needed for these refractory bricks will certainly be excellent. Better still, you must work with earlier mentioned reliable suppliers who fit in to pre- trusted quality system. This kind of partnership is essential for us to provide paralleled content. That entails constantly evaluating materials to drive its suitability for the task. In addition, it is important to also keep the materials in control so they are not damaged and that you find them there when you want its use as well. It will keep the materials from getting quite so dirty and breaking down.

The New technology comes up and new Studies always suggest on how to create a better refractory brick material. Materials that can handle even higher temperatures and more extreme conditions are developed as manufacturers only get better over time. New materials such as silicon carbide and carbon fiber are today being developed to increase the strength of these bricks — extending their life even further. These developments in material science are certainly necessary to make the performance of castable refractory cement better. When new materials are introduced, refractory bricks only continue to perform better and last longer so they will still be viable in the long-run unless other options prove superior for a specific application.

Kaifeng Datong Refractory bricks raw materials Co., Ltd. was established in 2008 and is a private joint stock company located in Henan province. It specialises in the manufacturing, development and sale of high-quality refractory material.

Datong invested 10 million yuan and built a chemical analysis laboratory which includes a Refractory bricks raw materials with a scanning electron microscope application laboratory high temperature laboratory, pilot base and more than 40 sets various tests instruments, such as SEM energy spectrumrometer XRD XRF laser size analyzer and various other world-class test and analysis equipments. The technical center employs more than 10 technical personnel comprising 1 senior engineer and 2 engineers. Datong maintains a close cooperation with Wuhan University of Science and Technology Sinosteel Luoyang Institute of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of the field of refractory.

We Refractory bricks raw materials high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

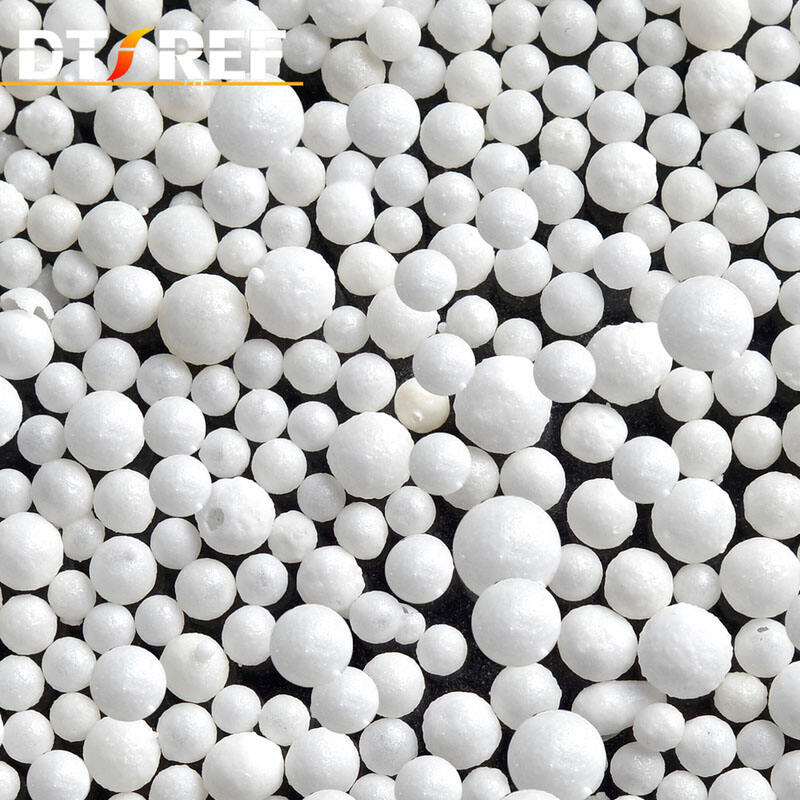

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code Refractory bricks raw materials. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog