These types of balls are those special kinds of balls which are needed for a lot of works, but one is not able to remember the name, then you should know that it are the alumina ceramic balls. Jobs that fall into this category are chemical production, resource mining, ceramics manufacturing. Its features are quite helpful in these industries as well since they have certain unique properties that makes them ideal for various tasks.

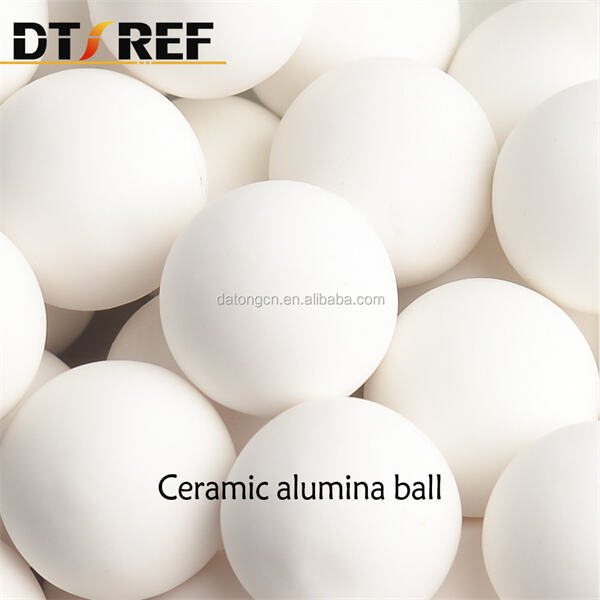

Many features, and good things are here for a business while they use alumina ceramic balls For starters, they are hard and nearly untearable which means they last very long, the same as Datong's boiler refractory cement. This makes them more resistant to the durability of use, even though they are the same conditions. Secondly, chemically they remain unresponsive. This means that, if they are used in other jobss, they will not mix or spoil whatever chemicals both are in the course of use. It is important because from this, they can be assured of the safety in protecting chemicals or not to become damaged by any sorts of chemicals that alumina ceramic balls used. Finally, these balls can take a lot of heat, which is extremely important. It is Highly resistive to very high temperatures, which means it is safe in hot locations and can be used for high temp applications.

Alumina ceramic balls are produced by using alumina powder as the foundation, also the fire clay cement developed by Datong. These balls are produced by blending alumina powder with water and a binder, similar to the texture of glue. These balls are dried into the dry form. The balls are then dried and fired in a hot kiln which makes them very tough and strong. This is how the alumina ceramic balls get their characteristic.

These ceramic beads are used in a number of ways. They could, for instance be used to grind substances in ball mills. They are made to take one thing and make it into a fine powder, which is crucial for all manufacturing. Before you know it, you are also able to do some chemical reactions quicker with a bit of help from the alumina ceramic balls. They serve as medium for these reactions to react more effectively. They also improve the strength and resilience of ceramics, improving the overall end products.

There are a lot of aspects to consider when it comes to the use of alumina ceramic balls, but they make working easier and more efficient, similar to the Datong's product like activated alumina ball. One, they are able to grind materials significantly faster than most, if not all other methods on the market. This is a way to produce it much faster and thus save money on the production. And also, they can enhance quality in the final products as well by delivering a more consistent and even grind. Consistency in the grind of a product will result in higher performance and will help the product meet its specifications. Also, the utilization of alumina ceramic balls plays a significant role in saving machines from damage. This is significant as it will help for businesses to save a massive part of their income in repair, maintenance costs and replacement components.

They also provide many businesses with a strong and cost-effective alumina ceramic balls, also the alumina production produced by Datong. They are also durable, so you can get a good amount of use out of them before having to replace them. It paths out economically in the long run. Furthermore, since they are nonreactive to chemicals, they can be employed for different environments safely without the risk of a detrimental reaction. And since they are be able to tolerate heat, their long life reliability in high temperature set-ups is a fact. With the output of this factor, Alumina ceramic balls are a good investment among all businesses that look for durability and quality in their equipment.

In fact, these balls are very helpful for work that includes high temperature, as well as the Datong's 3000 degree castable refractory cement. They can work in chemicals, mining and ceramics industries. They are very practical for work related to metals or glass due to their extreme temperature resistance. For the tough work to ensure ceramic ball can be exert itself on these high-heat applications, strength and reliability of alumina ceramic balls is indispensable in success.

We offer high-quality raw materials, premium products and services, while advancing with our clients. At the same. in order to better serve customers by providing customers with additional similar quality products Alumina ceramic balls is willing to create an environment of win-win with all partners!

Kaifeng Datong Refractories Co., Ltd. was established in 2008 and is a Alumina ceramic balls joint stock company located in Henan province. It is specialized in the production and distribution of high-quality refractory materials.

Datong has been awarded Alumina ceramic balls quality system certification, is014001 environmental management system certification OHSAS1800 occupational and safety management system certification, is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code 836236. Nowadays, it has become the largest and most complete quality aluminum-based refractory raw material base. Each tank is scrutinized by means of a hydraulic test and radiography test, and air tight test, etc. The most advanced production machines in the world guarantee strict quality control at every stage of production. We pay close attention to every detail, and every little thing is a part of our workforce.

Datong has a budget of 10 million yuan and has built a chemical analysis laboratory and a micro-powder testing laboratory with a scanning electron microscope Application laboratory, high temperature laboratory and pilot base, including more than 40 sets of testing equipment, including SEM and Alumina ceramic balls, XRD, XRF, laser particle size analyzer, as well as other top-of-the-line analysis and testing equipments. The technical center employs more than 10 technical personnel with 1 senior engineer and two engineers. The center maintains the close collaboration with Wuhan University of Science and Technology Sinosteel Luoyang Insimuie of refractories research, University of Science and Technology Liaoning, Zhengzhou University and other research institutes within the area of refractory.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog