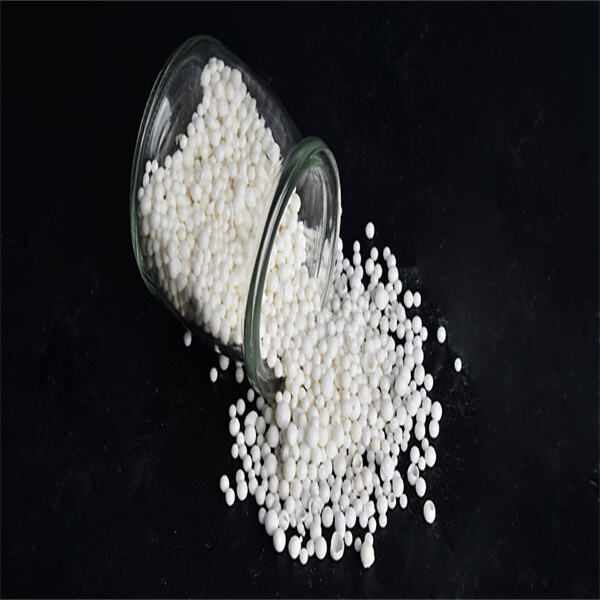

Bauxite is the rock from which high purity alumina powder is produced. Alumina ball is a naturally occurring mineral that contains aluminum. The bauxite that we process crystallizes to a white powder which is ultra clean and pure. High purity alumina powder as we call it. We make a lot of thing using this amazing powder like ceramic products etc for both homes and industries. It is also used to manufacture LED lights, which are high-intensity and low-power-consuming. Aside from those few examples, a powder of high purity alumina is also used in the electronic devices we use daily such as smartphones and tablets. It has a role in creating medical instruments and advanced batteries too

The incredible durability and high melting points of truly pure (low 99% alumina) make this a great reason for why high purity powder is so important. This property makes it ideal for high heat applications (furnace linings where material can be very hot) in industry. Because high purity alumina powder odor resistance is very good. This makes it able to be used in places like factories where accurate safety checks are made against strong chemicals.

Alumina powder for polishing is also known as one of the best material for high tech businesses. For example, computer chips in daily-life electronics and artificial joints to assist the handicapped – (it) is also used by many other products. This powder is extremely robust and durable, making it an absolute treasure trove for a wide range of new technologies

A typical example of this is the use of Datong high purity alumina powder in making lithium ion batteries - the type that run extensive numbers electric cars and mobile phones. Simply we can say that these batteries are the life savior to use technology in a better and reasonable way. Some technologies require high purity alumina powder to function at near their full potential, and without them we would lose a substantial portion of the conveniences that surround us.

It is a meticulous operation, creating Datong high purity alumina powder. Brown alumina in a processor to reduce bauxite ore into aluminum oxide After this, the aluminum oxide is converted into high purity alumina powder. There are special tools and expertise required to ensure that the powder is not just pure but possesses all those qualities which make it useful in its various purposes.

Datong brown corundum to extremely high temperatures in a furnace produces the actual powder. The process of heating forms one strong crystal structure that is pure and powerful. After the powder is developed, it undergoes washing and drying processes in order to get rid of impurities. Then it gets ready for a variety of uses in a number of industries.

For instance, one application in research involves utilizing Datong refractory cement to 3D print advanced ceramic geometries. This is a ground-breaking development because it may transform how we think about manufacturing complex parts and products in the future, much more efficiently and effectively than ever before.

Datong has been awarded ls0900l quality system certification, is014001 environmental management system certification, OHSAS1800 occupational health and safety management system certification. is a national high-tech enterprise which was able to be listed on April 7th, 2016 with stock code High purity alumina powder. Datong is now the largest and most complete collection of high-quality aluminum-based refractory materials. Every tank is inspected with hydraulic test, radiography test, and air tight test, etc. With world's advanced production machine and strict quality control at each production stage. We pay attention to each and every aspect, and each small action is an integral part of the workforce we employ.

We High purity alumina powder high-grade raw materials, a variety of valuable items and services while advancing with our customers. In the same way. in order to better serve customers by providing customers with additional similar products of a high standard, Datong Company is willing to create an environment of win-win with all its partners!

Datong invested 10 million yuan and built a chemical analysis lab, micro powder testing room, scanning electron microscope, application laboratory High purity alumina powder as well as a pilot base. There are more than 40 sets various testing instruments including SEM energy thermometer XRD laser particle size analyzer, along with other world class testing and analysis equipment. The center employs more than 10 engineers and scientists, including a senior engineer, as well as two other engineers. The center also has a close cooperation with Wuhan University of Science and Technology and the Sinosteel Lioyang Institute of Research in Refractories University of Science and Technology Liaoning and Zhengzhou University.

High purity alumina powder Datong Refractories Co., Ltd was established in 2008. It is a high-tech joint-stock private enterprise in Henan Province, which specializes in the development, production and distribution of premium refractive raw materials and related products. After years of continuous development the company now has an annual output of 30.000 tons of high-temperature alumina powder, 20.000 tons of magnesium aluminum spinel (electric melting the sintering) 10, 000 tons of calcium aluminate, 50, 000 tons white fused alumina, tabular alumina. There are 8, 000 tons of non-crystalline calcium aluminate, 30000 tons of high-alcohol cement, and 50, 000 tonnes of various castings and shaped products.

Copyright © Kaifeng Datong Refractories Co.,Ltd All Rights Reserved. - Privacy Policy- Blog